JetXpert Print Station

The Print Station offers world-class analysis at production speeds and repeatability, handling the most demanding printing applications with confidence.

Complete flexibility to choose one or more printhead models with any number of colors

Print on any substrate of any size, whether it comes in a box or a roll

Space to experiment with surface pretreatment systems to improve quality and adhesion

Compatible with any curing or drying system with adjustable speed, intensity, and timing

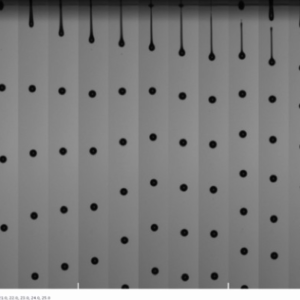

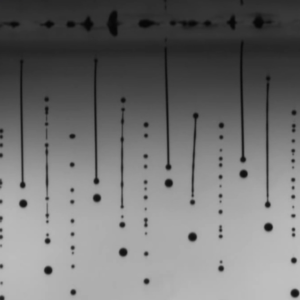

Built for process improvement with integrated dropwatching and print quality inspection

Accurately control sample and print placement down to the micron with automated fiducial alignment systems

The Print Station is built for change. Easily swap between printhead models in minutes to test the latest models, or scale up from one color to four once you’ve found success. Every setting across all aspects of the printing process is user-adjustable. The open architecture of the JetXpert Print Station means that anything can be controlled, measured, and optimized.

Learn More from Our Team

Customized Systems for Your Unique Application

This system was custom designed to pretreat, print, and cure on corrugated samples that range from 50 microns to 50 centimeters tall

Study dropwatching, printing, and curing of paints and coatings at any angle from 0 to 90 degrees

A custom-built larger system to auto-align, print, and cure flexible electronic parts up to 600mm x 600mm in size

Designed to print multiple layers on a roll of material with precision

This system incorporated a heated chuck, wafer rotation, and a camera to study drop-substrate interaction with the goal of minimizing printed layer thickness

JetXpert is Trusted by the Pros

FAQ About the JetXpert Print Station

- What makes the JetXpert Print Station unique?

- How fast can it print?

- How wide of an image can it print?

- How many colors can it print?

- What is the stage’s repeatability?

There are other inkjet printers that are flexible for experimenting. There are other inkjet printers that offer production speed and precision. But the JetXpert Print Station is the only system in the world that offers both. Plus it offers the industry-leading inkjet analysis tools, with a design that is customizable to make any application possible.

The speed of the linear stage systems is adjustable from 0 to 2 m/s and can be set by the operator through our software interface. Roll-to-roll systems are designed to your speed requirements, with ranges from 0 to 4 m/s. Custom versions of both are available if you have a need for speed.

For single pass systems, the maximum width of the image is the width of your printhead bank. With our Multipass Add-On, images up to approx. 440mm wide can be printed. But the system is customizable for even larger sizes if needed.

This is custom-built to your needs. Most of our customers are printing between 1 and 4 colors on the Print Station.

We are proud to say that our stage repeatability testing results are <1.5µm. Using our inks and waveforms, we have also demonstrated 1.5µm print print repeatability.

Whether you are looking for a quote, demo, or training on our industrial multipass printing system, we’d love to hear from you.