Print Station Add-Ons

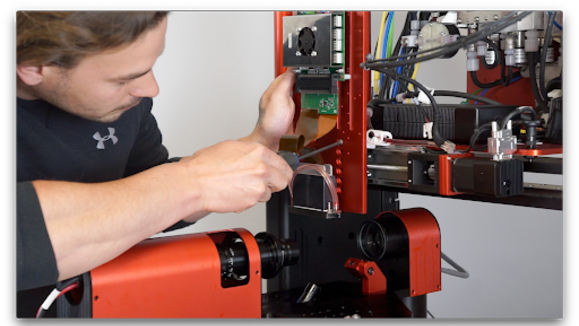

Additional Printheads

Integrating additional printheads with the JetXpert Print Station is easy – whether you want to print with multiple heads at once, or frequently switch between different printhead models.

Multiple-Color Printing

The JetXpert Print Station can be upgraded to print with multiple fluids or colors at once. This allows you to test the interaction between fluids on the substrate through measurements like intercolor bleed, mottle, and more.

Multipass Printing

If you want to increase the printed image size or resolution, the JetXpert Print Station can be fitted with a motorized, perpendicular axis to enable multipass printing.

Drying / Curing Station

The JetXpert Print Station is compatible with drying and curing stations from all major manufacturers, allowing you to easily experiment with different speeds and intensities to perfect your process.

Enclosure

Industrial printer components are sensitive to the surrounding environment, so it is best to replicate production conditions in the lab. Whether you want to control the temperature and humidity around the system, or contain and extract the jetted fluid, this enclosure is the perfect starting point.

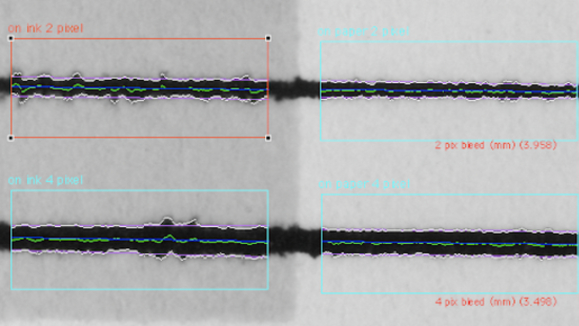

Print Quality Analysis

Easily integrate one of our inspection systems into the Print Station to perform print quality analysis on the printed samples. This system is custom-built for your substrate, ink, resolution, and speed requirements.

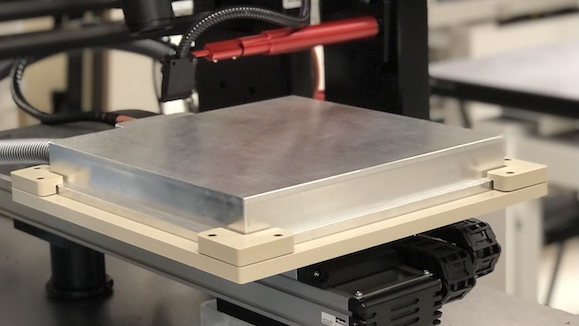

Heated Vacuum Chuck

Compatible with single pass, multipass, and three-axis JetXpert Print Stations, the Heated Vacuum Chuck has an adjustable surface temperature up to 125 °C.

Motorized Printhead Positioning

The JetXpert Print Station can be configured with a motorized Z axis to accurately control the printhead height from the software. This allows quick, easy transitions between dropwatching and sample printing while tightly controlling the print throw distance. You can also print multi-layer prototypes with full three-axis automation for applications such as material jetting or printed electronics.

XSweep Print

Automate your jetting optimization, sample printing, and print quality analysis with XSweep Print. Choose a parameter like waveform, voltage, throw distance, resolution, etc., and XSweep will sweep through a range of values to find the optimal one.

Read More