JetXpert Add-Ons

Tools Built for R&D

With over 500 systems in the field, we hear a lot of great ideas for ways to expand the platform’s capabilities. We’ve listened and built a suite of upgrades to make your development faster, smarter, and more tailored to the challenges of inkjet R&D.

Upgrade At Any Time

The JetXpert platform is modular, so you can build your system over time as your needs and budget change. Most drop watcher add-ons can be upgraded remotely, so your system never stops working for you.

Wetting

Add a second camera to your JetXpert to visualize the nozzle plate and monitor ink buildup. Simultaneously view the drops and the nozzles to understand the causes and performance impact of wetting, debris, or damage on the nozzle plate.

XSweep

Make the process of waveform optimization more automated with XSweep. Simply specify which waveform parameter you want to adjust, like voltage or pulse width, and enter a range of values to test, and the software will automatically capture images and data for each one.

Read MoreVacuum Ink Collector

Inkjet printing on a dropwatcher is messy, unless you have the Vacuum Ink Collector. Capture mist as soon as it leaves the printhead, without impacting the jetting performance, to keep your workspace clean and safe.

View Brochure

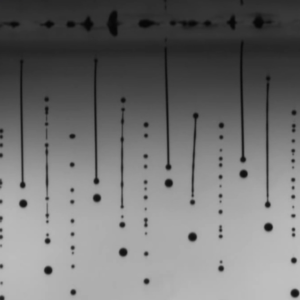

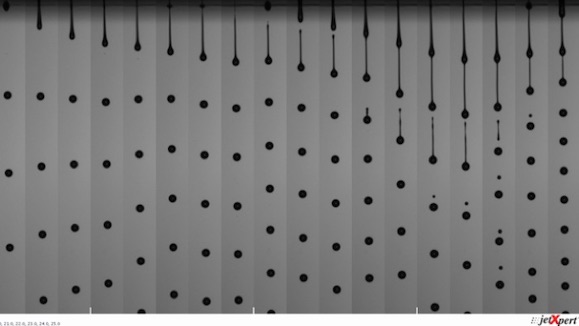

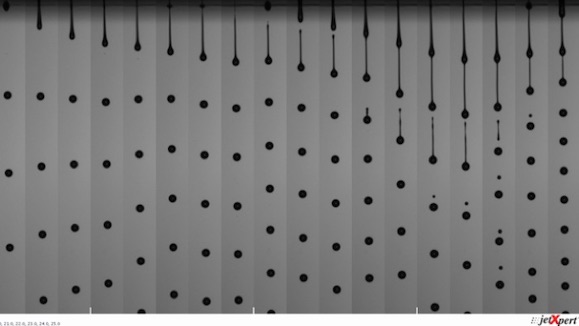

Stitch

Automatically generate a single image comparing a range of drops, nozzles, waveforms, frequencies, idle times, and more. Pairs with other JetXpert Add-Ons like Frequency Sweep, XSweep, Latency, and more.

View BrochureMotion

Automatically scan the entire printhead while performing analysis to ensure consistent performance across all nozzles. Scheduled scans automatically check all nozzles to study sustainability and log missing jets over time.

View Brochure

Latency

Instead of performing latency or open time testing with a stopwatch, easily determine the maximum idle time, or minimum recovery time, for your ink by testing different combinations automatically. Enter a list of idle times you want to test, and let the software take over by capturing images and data for each one.

View BrochureDrop Tracking

Whether you are formulating an ink, optimizing a waveform, or designing a printer, monitoring the change in drop velocity vs. throw distance is crucial to understanding the final print quality. That’s where Drop Tracking comes in; just specify a range of distances to measure the drop across and it automatically will reposition the drops and capture their velocity.

Capping Station

At the end of the day, developers often have to choose between the time consuming tasks of cleaning out their printhead now or recovering dried nozzles later. With the JetXpert Capping Station, you can skip both and quickly create an airtight seal around the nozzle plate to prevent the ink from drying.

View BrochureNozzleXaminer

A portable microscope that can be inserted underneath the printhead to quickly check for scratches, worn coatings, or debris on the fly. Diagnose the causes and understand the performance impact of damage to the nozzles or nozzle plate.

View Brochure

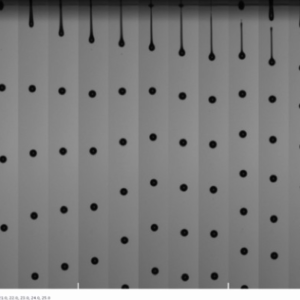

Frequency Sweep

Automatically ensure that your jetting is consistent at any printing speed. Frequency Sweep lets you enter a list of firing frequencies to test, and the software will automatically collect images and data for each one.

View Brochure

Enclosure

A custom-built enclosure perfect for controlling the environment around the JetXpert or JetXpert Print Station. Comes as a kit that can be combined with your in-house fume extraction system or temperature / humidity control system.

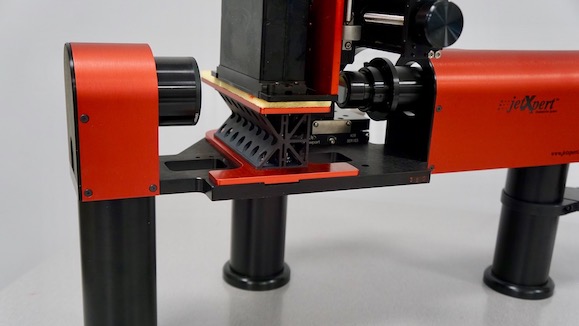

Surface

See drops hitting the substrate with your JetXpert system to study splashing, spreading, powder movement, and more. This is not your father’s contact angle measurement tool – these are actual-size, jetted drops in a printing environment.

View BrochureReady to Supercharge Your JetXpert System With Drop Watcher Add-Ons?

JetXpert is Trusted by the Pros

FAQ About JetXpert Drop Watcher Add-Ons

- Can these add-ons be used with my existing JetXpert system?

- Do I need to return my system to ImageXpert to be upgraded?

- Which add-ons are right for me?

Yes! From the very beginning, we’ve designed the JetXpert platform to be modular, so you can add any add-ons at any time.

We know that putting your projects on hold while you send your system to us is not always easy, so we do our best to upgrade the systems remotely as often as possible. We examine each upgrade on a case-by-case basis, and only the most complicated hardware upgrades require the system to be sent back to us. Even in that situation, we expedite your order so that the system is returned back to you within days.

There are definitely jetting issues that are common to specific industries, so based on your industry and the type of fluid you are using, we can predict which add-ons will most likely be needed. If you are just getting started with inkjet and unsure what to expect, reach out to us and we are happy to explore your application and make recommendations.

Whether you are looking for a quote, demo, or training on any dropwatcher add-ons, we’d love to hear from you.