Print Quality Analysis

Understand the Big Picture

When you want to optimize your entire printing process, you need a way to evaluate your entire printing process. Print Quality tools analyze the end result, the printed image, so you can measure the output of hundreds of parameters at work in one easy test

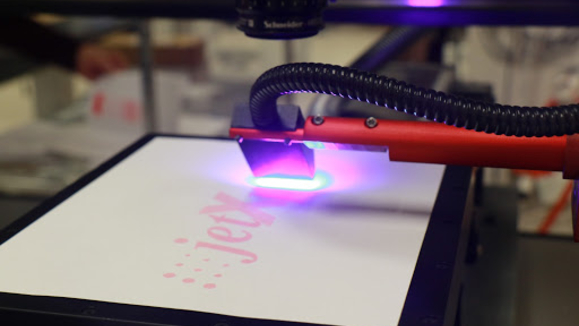

Study Substrates, Pretreatments, Curing, and More

A lot goes into determining how good the final printed image will be: your choice of substrate, pretreatments, curing/drying method, and more. Just as dropwatching reveals everything going on in the jetting, print quality analysis shows you everything happening once the drop hits the substrate.

One Familiar Platform

The same ImageXpert software is used across all of our systems, so one platform analyzes everything from drops in the air to dots on the page

Standalone or Integrated Options

Whether you want a standalone system for the lab or want to add print quality analysis capabilities to your JetXpert system, we’ve got a solution for you

Common Analysis Options

- Dot Positioning

- Test Target/Graphics

- Coupon/Nozzle Pattern

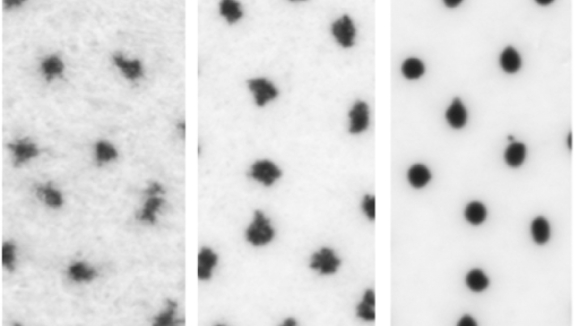

Dot Positioning

For applications demanding the highest precision, or for those who want to understand every detail. This print quality analysis test measures individual dot size, shape, and position in high resolution, which can give you insights into the entire printing process.

View Systems

Test Target/Graphics

For when you want to grade a printing process, or compare your system to the competition. Printing and then analyzing these test patterns will help you turn a qualitative image into quantitative data.

View Systems

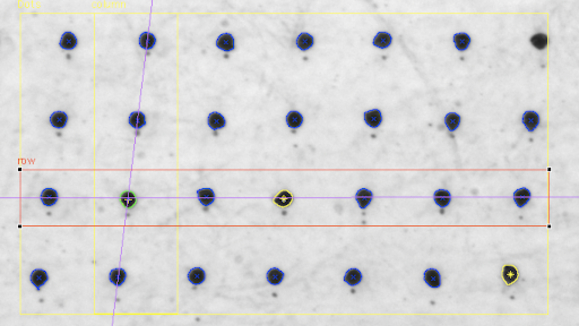

Coupon/Nozzle Pattern

For when you want to evaluate the health of a printhead, or check the alignment of your printhead array. These patterns are designed to differentiate each nozzle so our software can automatically detect defects.

View SystemsSee How Print Quality Analysis Can Improve Your Printing Process

More on Print Quality Analysis

Print Quality analysis, or the inspection of the printed image, plays many roles within inkjet R&D and production. Most print quality analysis tests break down images into dots, lines, and text and perform specialized measurements on them to learn more about how the system is performing. They look at things like are there any missing lines in the image, is the pattern uniform, or is the color bleeding between two adjacent inks. There is a broad spectrum of ways to perform print quality analysis: from looking at a printed sample with your eye to judge how good it looks to you, all the way to robust machines that can scan and measure the image automatically. These automated machines are used in quality assurance, system setup and calibration, as well as in R&D to optimize the printing process.

Print technicians utilize print quality analysis as a means of determining the health of their printers. Special patterns, called coupons, are printed and analyzed to determine if all of the nozzles on the printhead are working properly. These coupons are scanned by a software program that is able to count the number of lines and determine if any are missing or deviated. If there are nozzles missing, this can be programmed into the printing software so it can compensate by overloading adjacent nozzles. If the printer contains many printheads, these patterns can also be used to check the alignment of the heads. Aligning printheads is a critical step towards ensuring that the images are properly printed, especially in very sensitive applications like printed electronics or additive manufacturing, so high resolution camera systems are used to analyze the printouts and help correct misalignments.

In R&D labs, image quality analysis is used to help optimize the combination of substrates, pretreatments, and post-processing through measurements and data. There are dozens and dozens of variables beyond the jetting that have an impact on the final printed image; just using a UV curing lamp as an example, you are looking for the right combination of the intensity, height above the substrate, time since printing, duration of the curing, and wavelength of the light. Multiply this across different substrate materials, pretreatments or coatings, transport mechanisms, printing speeds, and more and it becomes clear that finding the right combination in an efficient way requires some sort of consistent measurement criteria. Print quality analysis is designed to break down the image into measurable components and automatically grade the print with numbers, allowing you to make improvements over time.

The benefits of utilizing print quality analysis simultaneously with drop-in-flight analysis are often overlooked. While a dropwatcher is able to tell you the volume and velocity of your drops, it does not tell what the volume and velocity of your drops should be. This is determined by analyzing the printed image itself and studying the drop size and placement relative to your application requirements. With both tools on the same machine, developers are able to quickly perform tasks like optimizing waveforms based on feedback from the drops in the air as well as the drops on the substrate. By studying both, developers are able to draw conclusions and make progress much more quickly, and know the results they are getting will translate well into production.

Whether you are looking for a quote, demo, or training on a print quality analysis system, we’d love to hear from you.