Metal Strip QA

Automated Quality Assurance

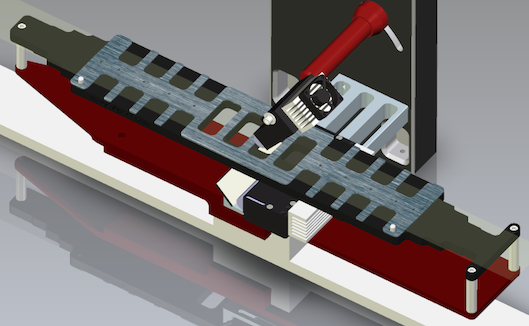

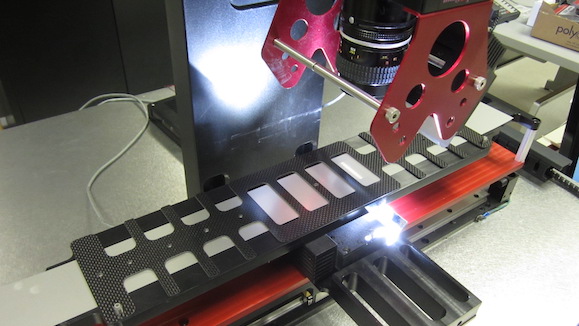

This system incorporated a linescan camera, RGB frontlight, powerful backlight, linear stage, high resolution optics, and custom machine vision application to perform micron-level dimensional measurements of metalized strips and inspect each surface for tiny scratches and pinholes

Ultra-Precise Analysis

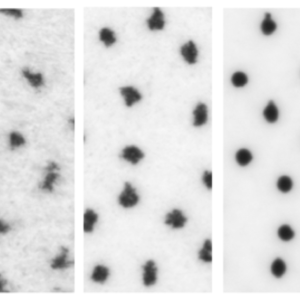

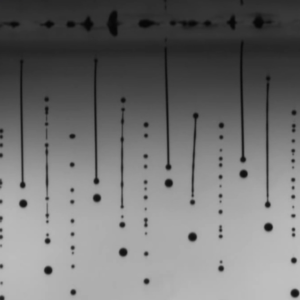

The system is capable of measuring tiny pinholes, while still capturing large scale images at high resolution with negligible optical distortion. Customized lighting achieves high contrast, optimal illumination while a custom-built program uses powerful machine vision algorithms to automatically detect and measure the features and defects most critical to the application.

Trusted Machine Vision Integration

Let’s Talk

Whether you are looking for a quote, a demo, or more information about a system for metal strip QA, we’d love to hear from you.