Does My Ink Need Degassing?

Last Updated on June 25, 2024 by ImageXpert Team

Degassing, sometimes called de-bubbling, involves the extraction of dissolved gas or microbubbles from the bulk ink. In this post we describe the positive effects it can have on your jetting performance and why you should consider adding it to your ink supply system.

THE THEORY BEHIND DEGASSING

As you know, piezoelectric inkjet printhead operation relies on the compression of ink in the nozzle channel to form a pressure fluctuation and cause the ink to jet. Because the process is mechanical, it can be severely impacted by the presence of gas bubbles. There are two common sources of gas bubbles in the nozzle channel: atmospheric air and dissolved gases. To combat them, you have to keep atmospheric air out of your system with the correct ink supply pressure settings, as well as prevent growth of bubbles from dissolved gasses by using degassing techniques.

The mechanism by which bubbles can grow in an acoustic field is known as “rectified diffusion” and is commonly used to explain why degassing can be helpful. By reducing the dissolved gas levels within the ink, net gas diffusion into a bubble is minimized, whether that bubble was originally ingested or entrained by a leak in the system.

DEGASSING TECHNIQUES

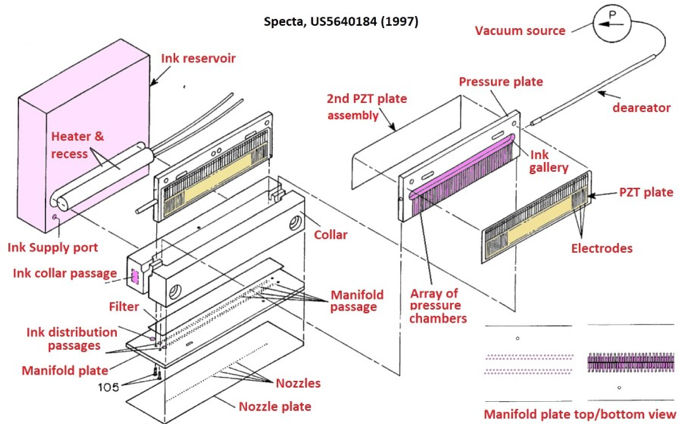

Because the benefit of degassing was established early on, some printhead designs have incorporated a deaerator into the head itself. An example from Spectra/Dimatix is shown in the image below. Their “Miata” reservoir for S-class printhead series also included a lung degassing component.

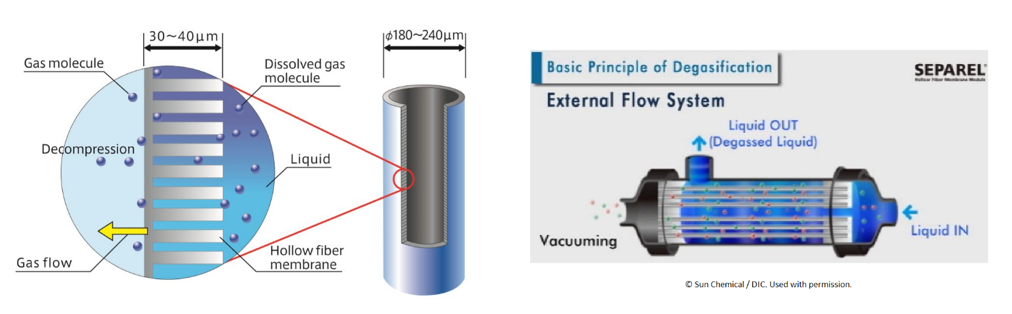

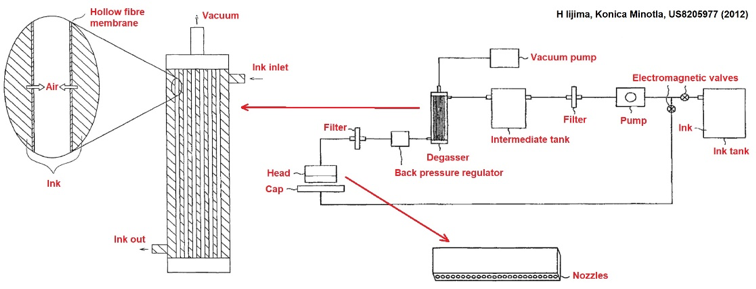

Perhaps more familiar these days is the concept of a separate, membrane-based degassing unit. In these devices, which are available in many different sizes and configurations, the gas is removed by pulling a vacuum across a membrane as the ink passes through it.

When selecting the right components for degassing, the two most important variables are the ink flow rate and the amount of vacuum applied. The latter tends to be limited to 600-700mbar vacuum (300-400mbar absolute) in order maximise degasser lifetime by limiting vacuum failures. This leaves your system’s total ink flow rate as the main consideration, which will determine the size of the degas membrane to use. Usually manufacturers specify what flow rates are appropriate in the technical specifications of a particular degas matrix model. In recirculating system designs, the size can be decreased a little because the ink will pass through the membrane multiple times. However, this does depend on the ink system volume and ink consumption since new ink that has not been degassed will be introduced upon printing.

HOW TO TELL IF YOU NEED DEGASSING

The amount of dissolved gas and bubbles allowable in the ink chamber depends on several key factors:

Am I printing at a high frequency?

The higher the frequency that you are jetting, the more movement there is inside the nozzle, and the more likely it is that bubbles will be formed and reduce performance.

Does my waveform have more than one pulse?

Multi-pulsing also causes extra movement inside the nozzle, making the printhead more sensitive to acoustic effects.

Am I printing small drops?

The amount of ink inside the nozzle will determine how much air is enough to alter its motion. Small drops are much more sensitive than large ones.

Is consistent jetting important?

If a missing or misbehaving jet is a problem for your system, then degassing is more important.

Am I using water-based ink?

A general rule of thumb is when using water-based inks, degassing can be essential. The growth in textiles and the high-productivity end of the market has emphasized the positive influence of degassing and the benefit to reliable performance as mainstream printers.

Depending on how many of these questions you answered yes to, you may discover that degassing is something you should be adding to your system. It might be that you ink manufacturer already degasses the ink at source. If your system can be designed with a sealed ink delivery system (such as collapsible foil bag), it might reduce your need for additional degassing. However, for truly industrial printing, where the ink is either poured into the tank or there are limitations on complexity of packaging needed to maintain the degassed state, additional machine-based degassing is needed.

Join Our Mailing List

WHAT ABOUT FOAMING?

Many people wrongly connect the negative effect of foaming in inks when they are pumped with the need for degassing. Degassing only reduces the equilibrium gas content of the bulk fluid; it will not solve the potential for air entrainment by turbulent flow at a fluid free surface, such as the return reservoir in a recirculating ink system. Even a degassed fluid can generate foam in a reservoir when it is recirculated. You may find that investigating the meniscus and recirculation pressure settings provides better results.

Another possible cause for air in the system and foaming is the waveform. If the nozzle ingests air by overdriving or severe nozzle wetting, then the resulting air entrapment may show as foam-like bubbles when purging the head to recover it.

INTEGRATING DEGASSING INTO YOUR INK SUPPLY SYSTEM

Because a degasser can produce a small pressure drop, it is important to position it in a spot where flow variation will not impact system performance. The correct location really depends on your system design, but there are several candidates.

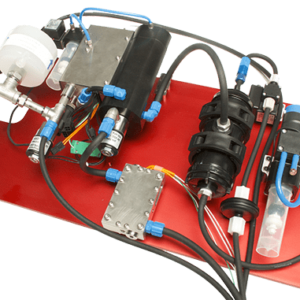

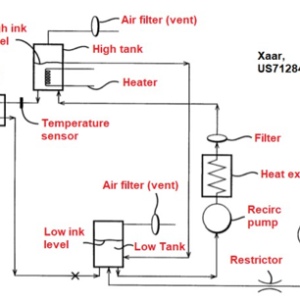

For non-recirculating printheads, manufacturers make different size degas matrixes intended for different locations. Small, low flow rate units are available that are suitable for putting just before each individual printhead in the system. As shown below, it is important to regulate the pressure after the unit, because of that drop in pressure. If there are many printheads in the system, larger units can be placed before the intermediate tank, thus serving all of the printheads.

If the ink supply system is recirculating, there are a few considerations for placement. First and foremost, it is important to ensure that fresh ink from the bulk tank passes through the degas matrix before entering the printhead. Second, it is also important that the pressure drop across the matrix is accounted for using either a sensor following it, or by positioning it in a spot where the pressure doesn’t matter. If you want the ink to pass through the degas matrix only once, it might make sense to position it between the bulk ink tank and the intermediate tank or reservoir that feeds the printheads. If you want the ink to potentially be passing through the matrix multiple times, putting it somewhere between the intermediate tank and the printheads would work.

HOW CAN I MEASURE EFFECTIVENESS?

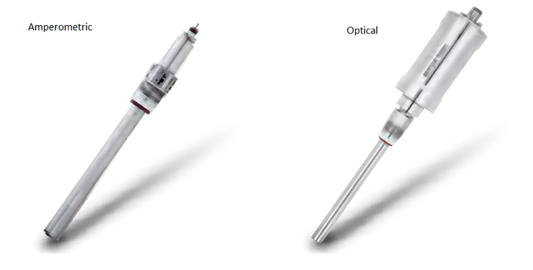

Although it comprises only 18% of the Earth’s air, the level of oxygen in the ink is often used as representative of the amount of dissolved gas because it can be detected more easily. In lab situations, the typical measurement arrangement might involve a galvanic device or polargraphic head. These are less adaptable to different fluid types so in more industrialized processes an optical sensor using fluorescence quenching, and especially one that can be mounted in-line, may be more appropriate.

Measurement ranges for these devices are typically quoted as mg/L but establishing a relative % gas level compared to a non-degassed control is the best approach. Based on experience, reaching 30-40% saturation (or lower) should produce a discernible difference in jetting performance.

As with most things in inkjet, there are no hard and fast rules for degassing, and the only way to know for sure what level is appropriate for your system is to test it. If you notice sustainability issues in a particularly demanding application, and several of the key impactors match what you are doing, it might be worth running a quick test with a degassed fluid to see if the results improve. ImageXpert provides several turnkey solutions for laboratory ink supplies with integrated degassing capabilities built for such a purpose and would be more than happy to help you along the way.