Printer Development

ImageXpert Partners

ImageXpert has roots in the inkjet printing industry that go back over 25 years. The earliest ImageXpert systems for measuring print quality were used by the founding companies of inkjet technology. At that time, inkjet printers were primarily used for printing on paper and were produced by only a handful of well-known companies such as HP, Epson, Canon, Brother, and the like. Today, inkjet printing has infiltrated almost every manufacturing sector: from printing on textiles, to packaging, to printed electronics, to glass, and more. This wide range of applications calls for a wide range of printers, each with their own substrates, ink delivery and drying systems, as well as drivers and software. Today, there are hundreds of companies that pursuing industrial printer development, with more being added every day.

Common Challenge: Benchmarking Printers

One common challenge for printer manufacturers is benchmarking their printers to evaluate the results of changes to the mechanical systems, ink, waveform, and other aspects of the design. Just like changes to a car design are evaluated by their impact on fuel economy, horsepower, or torque, changes to a printer design are evaluated by their impact on dot and line quality, dot positioning, color reproduction, and other print quality tests. Without these tests to measure outputs in an organized way, a lot of industrial printer development is guessing and checking different combinations of settings. Using machine vision is the most common technique, but capturing high resolution images of drops on a variety of surfaces that could be shiny, transparent, textured, or a mirror is extremely difficult. This is where ImageXpert equipment shines.

Critical Measurement: Printer Maintenance

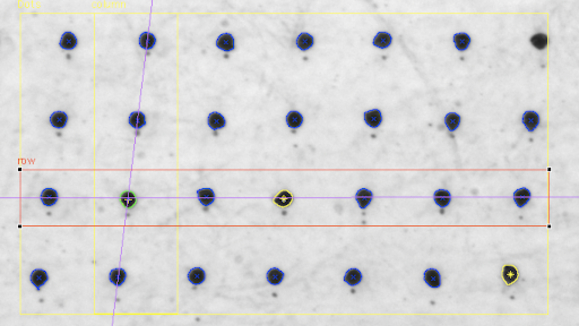

Even the smallest deviation of the dots, due to printhead misalignment or missing jets, is noticeable on the printed image, so printers that use 10, 50, or even 100 printheads per system spend a lot of time addressing these issues. To help automate this process, ImageXpert has tools that can check printhead alignment or identify missing jets by examining the printed image.

View Systems for Printhead Alignment and HealthCommon Challenge: R&D

Printer manufacturers are constantly evaluating new printheads and inks to see if they can improve the performance of their printers or design a printer for a new application. Rather than trying to do this development on their printers, where they are handling many heads and moving parts, they opt to use a lightweight system built for R&D like the JetXpert Print Station. When a new printhead, ink, or application is released, they simply add it to their JetXpert system and perform all the preliminary testing quickly before investing the time to put it into a production machine.

Critical Measurement: Inline Drop Analysis

Having an inside look at the jetting within your printer allows you to diagnose printing issues faster, improving production, maintenance, and support for their systems. In the most critical printing applications, drop analysis is used to verify the drop behavior and identify missing jets throughout production. We’ve introduced the Inline JetXpert, built specifically for integration into production printers.

Learn More About Inline JetXpertIf you are interested in industrial printer development and have questions about getting started in this groundbreaking industry, reach out to us and we will be happy to share our experience!

Recommended Products for Industrial Printer Development

- Dot Positioning

- Test Target/ Graphics

- Coupon/ Nozzle Pattern Analysis

- JetXpert Print Station

- Multipass Printing

Dot Positioning

The most demanding inkjet applications require critical dot size, shape, and position accuracy with drops as small as 1 pL in size. Our Dot Positioning systems perform analysis with micron-level resolution, so you are able to clearly see the smallest drops and satellites and perform accurate measurements.

Learn More

Test Target/ Graphics

As you make incremental changes to your printer over time, how do you systematically measure if you are improving? Rather than judging the samples by eye, our test target analysis systems will break down the printed sample into the most critical components and assign number grades to each one.

Learn More

Coupon/ Nozzle Pattern analysis

Nozzle-by-nozzle inspection for assessing printhead health and alignment. Easily scan a printed pattern to check for missing jets, deviated lines, or other printhead failures.

Learn More

JetXpert Print Station

All-in-one dropwatching, sample printing, and print quality analysis for more efficient testing.

Learn More

Multipass Printing

If you want to increase the printed image size or resolution, the JetXpert Print Station can be fitted with a motorized, perpendicular axis to enable multipass printing

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for industrial printer development, we’d love to hear from you.