What is Grayscale Printing?

Most modern industrial inkjet print applications make use of greyscale printing. In this outing, we are going to talk about the difference between binary and greyscale jetting, why grayscale has become so popular, and some of the considerations when designing a system around it. We are going to use terms like resolution and waveform quite a lot, so have a look at our previous posts on selecting printheads and waveform theory if you’d like more background.

BINARY VS. GRAYSCALE

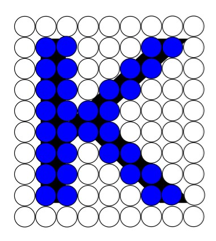

If you conjure the image of 1s and 0s in your mind when you hear the word “binary”, you may already have an idea of what binary means when it comes to inkjet printing. Just like data is reduced to 1s and 0s, a binary image is reduced to pixels that either have a drop or do not. All the drops are the same size and there are no in-between options. If we want to print a simple image of a letter “K” at a given size with the defined resolution, then we’ll put the drops in those pixels we want the ink to deposit, as in the picture here.

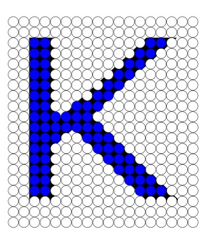

As you can see, this does not necessarily produce the most accurate rendition of the image. In order to improve the results, you can have a higher number of pixel positions where smaller drops can be placed. This is how office printers work in multi-pass – but it has taken time for inkjet heads to evolve to being able to do this in single-pass because it requires tightly packed nozzles and high jetting frequencies. The image here is the same K using smaller drops (higher resolution).

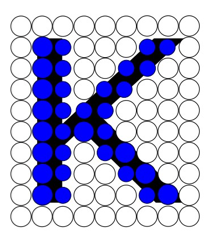

An alternative means of improving image appearance is using grayscale. If a binary image is black and white, a grayscale image is black, white, and many shades of grey in between. In an inkjet printing sense, this normally means that multiple drop sizes are possible at each drop position (pixel). With the ability to select from a variety of drop sizes for each pixel, you are able to more accurately produce a feature without having to increase the resolution. This letter K has the same resolution as before, but each pixel has two potential drop sizes (grey levels).

Side note: It is still possible to create images that have varying color density using binary, you just have to adjust the positioning of the drops so they are closer together for dark portions and farther apart for light portions.

HOW IS GRAYSCALE ACHIEVED?

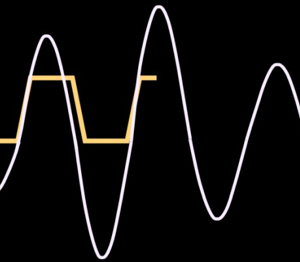

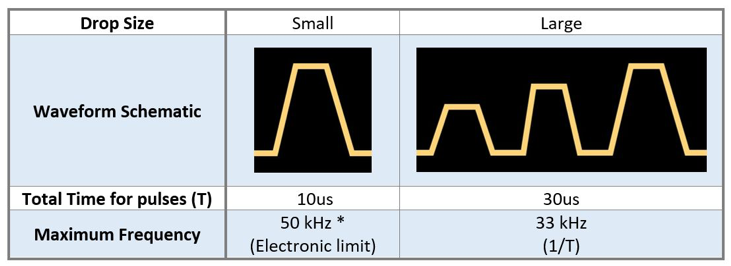

How can you get different sized drops out of a nozzle that is a fixed size? The answer is through the waveform! Because the waveform controls the acoustics of the ink in the nozzle, three different waveforms can produce drops of three different sizes out of the same nozzle. In practice, this is more commonly achieved by using a single waveform with multiple pulses, rather than multiple waveforms.

For example, you can develop a waveform with three identical pulses in it. If you want to print a small drop, Gray Level 1, you would only apply one of those pulses to the nozzle. If you want to print a medium drop, two pulses get applied, and three pulses for a large drop. With this setup, you have one waveform that can produce three different drop sizes, or Gray Levels.

In order to use greyscale, you need several of your system components to be able to process data with more than one bit of data per pixel position. Then your control system use can use your waveform to fire whichever drop size (via the correct number of pulses) the RIP chooses to use to make the best reproduction. This process is handled through the drive electronics for the printhead.

BENEFITS OF GRAYSCALE

As we saw before, higher resolution and grayscale are both techniques for improving the appearance of an image. Because increasing the resolution is already a known solution, you may be wondering why grayscale is even necessary. This is the case in displays, where if you want to improve how it looks, just decrease the size of the pixels. However, in inkjet, it is not so easy.

The challenge with inkjet that displays don’t have to worry about is that because the dots are deposited without contact, and have a low viscosity, they can move around. Once deposited, ink can wick based on surface tension effects, and will coalesce to form larger areas of colour. This can lead to discernible variation, called graininess, even when the raster pixel spacing is very small. Because the drops are closer together at a higher resolution, coalescence can get worse. Furthermore, if you are dealing with absorbent substrates, several smaller drops might lose their color more than the one large drop they are replacing.

In addition, higher resolution, smaller drops are not always a practical solution depending on your application. If you are looking for high laydown, such as coatings, adhesives, or 3D printing, it might take a very long time to put down drops 1 picoliter at a time when you only need that sort of precision at the edges.

Grayscale helps with this for industrial applications since you can get improved appearance with more control over coalescence, color, and laydown. Basically, you can get the benefits of both small and large drops in one system.