What is a Waveform?

Want to understand more about what waveforms are, how they work, and why they are a necessary part of your inkjet development? Good, because they are important and often not very well understood. In this post we will talk about the fundamentals of a waveform, and in the next post, you will find practical steps to go through the process of optimizing a waveform for your ink. Start here, and when you are ready to move on, learn how to optimize one here.

THE BASICS

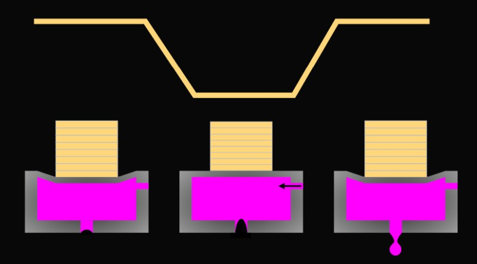

To help explain the purpose of a waveform, let’s take a look inside a nozzle chamber of a printhead. The image below depicts the jetting process known as fill-and-fire, which is quite commonly applied to many different printheads of varied design. In this case, a stack of PZT (a piezoelectric ceramic material) deforms whenever voltage is applied to it, changing the volume of the ink chamber and causing the ink to move within it and eventually eject. The means of applying this voltage to the PZT is the waveform.

In our example, the PZT is extended only when voltage is applied, so there will be no deformation until the printhead is plugged in. Once powered, the printhead maintains a specific voltage, causing the PZT to extend and remain in its non-jetting position (Left). If the voltage is decreased, the PZT retracts and creates an expansion in the chamber, drawing ink into it (Center). To eject a drop, the voltage is returned to its original value, the chamber shrinks, and the excess ink is forced out (Right). This process repeats thousands of times per second.

It is important to note that printheads can be driven by either positive-going or negative-going pulses, depending on how they are manufactured. Whichever way you’re used to looking at it, the important waveform timings are the two sloping parts and the hold time, i.e. how long the voltage is kept at that level (high or low) before it returns to the start position. This pulse timing determines what is happening at the nozzle when the volume of the chamber is returned to a steady state and is the first step to figure out when building a waveform.

PULSE TIMING BASICS

If you’ve stood next to a print head while it is printing, you might have been able to hear it “sing”, depending on what frequency was being used. The reason you can hear it is because the actuators produce sound waves. The most important ones for jetting are the ones that get produced in the ink itself, since they define the pressure variation that gives drop ejection.

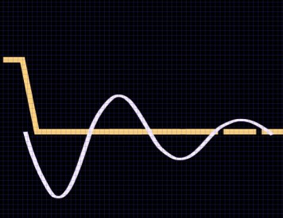

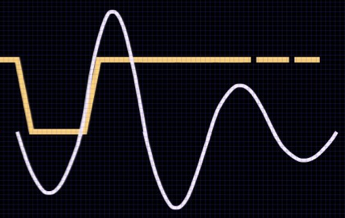

Because of the presence of an ink with certain mechanical properties, and the fact the sound waves can lose energy as they bounce around, the pressure in the chamber can be described as a damped resonator. Any change in pressure, such as the PZT deforming, will result in a characteristic pressure variation. As shown here, when the PZT retracts and the chamber increases in volume, the pressure change causes the ink to begin moving back and forth within the chamber.

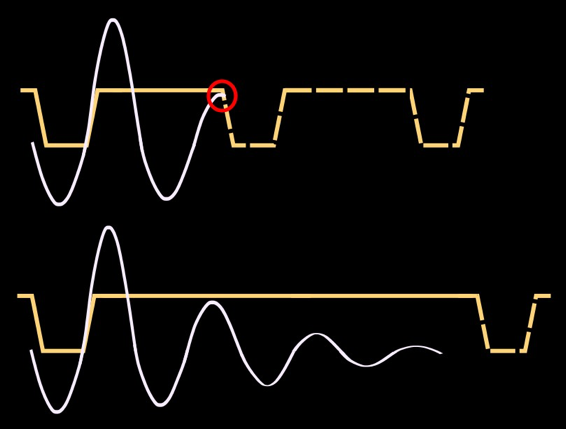

This energy alone is usually not enough to cause the ink to eject, it just pulls it back to the opposite end of the chamber and bounces off. By using a voltage pulse to reinforce the pressure at the right time, the drop ejection is made more efficient, as shown here. A drop is ejected when the pressure goes over a critical value due to the preferable timing.

The reason the pulse width is so critical is that if it is too short, or too long, then the waves, pressure, and movement of the PZT will be out of sync. If the ink is not moving the right direction at the time more pressure is added, instead of smoothly adding to the momentum, the momentum might be countered. It is similar to pushing a child on a swing. If you push them at the right time, the momentum is increased and they swing higher. If you push them at the wrong time, they will come to a violent stop. Similarly, if the pulse width is wrong, the resulting jetting, repeated over and over, will be inefficient and unstable.

Because the ink needs to move back and forth across the length of the chamber, the maximum frequency that a printhead can produce comes down to the size of the printhead chamber. Printheads that are designed with longer chambers take more time for the acoustic waves to travel back and forth, thus can’t eject drops as often.

Since the length of the nozzle chamber is fixed, you might think that the pulse width needed to correctly time the pressure wave is constant for a given printhead. However, the timing is also impacted by the speed of sound for that particular ink. This is why a waveform must be tuned for a particular ink and printhead combination, it is not enough just to have a general waveform for that printhead. Fortunately, if inks are similar in property, then the same waveform can work well for both.

Join Our Mailing List

WHAT IS RESONANCE?

It is common that a waveform that works well at one frequency might not work well at another. This all comes down to the timing of the pulses as the ink moves back and forth within the chamber. As the frequency of the printing is increased, the waves and movement created by a given pulse can start to interact with the previous one. At certain frequencies this is going to be reinforcing and the result is resonance, as in the top example in the image.

The higher the printing frequency, the more likely that the pressure is not yet damped to zero when the next drop and pressure wave comes along, and thus the greater the potential for getting poor firing. If the ink is still moving, the previous pulse could either add to the pressure (higher velocity, more satellites, wetting) or detract from it (lower velocity). If your print speed is flexible, it is sensible to study the droplet formation at a range of frequencies in order to ensure your final print speed does not fall in a frequency range where resonance occurs.

MULTIPLE PULSES

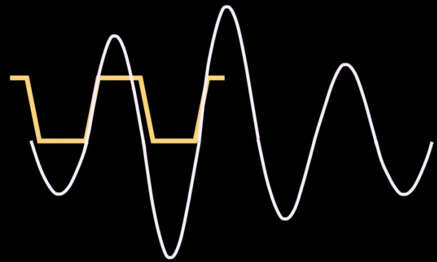

If the electronics allow it, then multiple pulses can be used at each pixel, allowing you to create larger, faster drops. Waveforms for multi-pulsing usually rely on the first or second resonance in the pressure wave. This means that the first pulse will add to the pressure of the ink when it is moving towards the nozzle. Some of the ink will eject and the rest bounces off the orifice and returns to the opposite wall. Once the ink is moving towards the nozzle again, a second pulse will add to its momentum. The pulses should be tuned carefully; the reinforcement can be very strong, overdriving the pressure and creating nozzle wetting.

If the pulses are the same amplitude, then the second drop ejected will be larger and faster than the first because it is building on the resonance of the previous pulse. It can merge at the faceplate or mid-flight, depending on several factors, including the head design, the pulse-to-pulse timing, the voltage used, and the ink property.

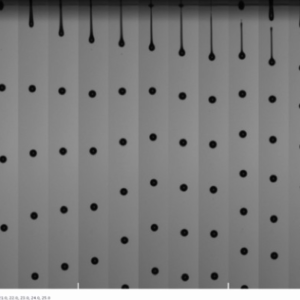

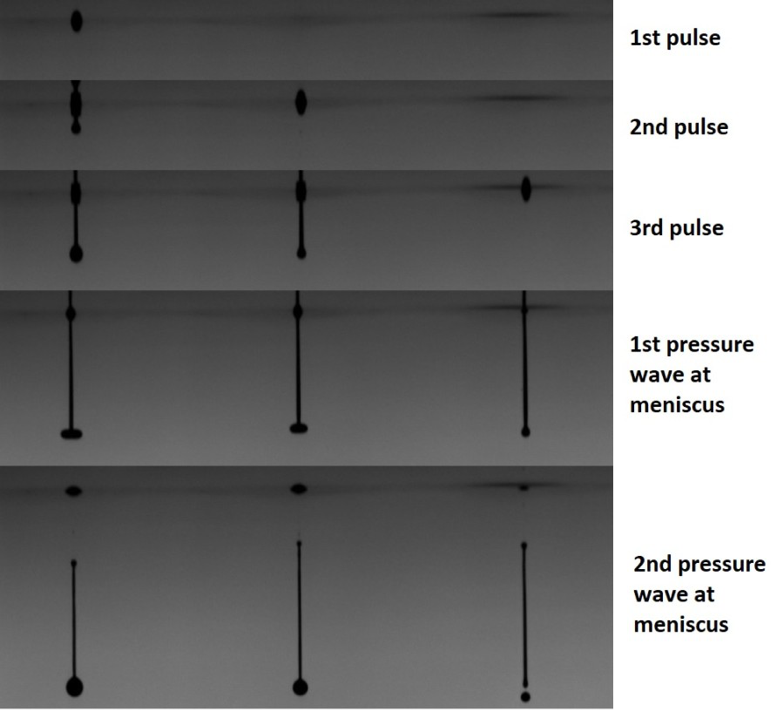

Having the ability to see the drop formation in real time is helpful in understanding these effects. In the photos below, taken with the JetXpert dropwatcher, you can see drops of different sizes being formed in adjacent nozzles by a resonant multi-pulse waveform. The nozzle to the left had three pulses of a waveform applied to it, the center nozzle only had the last two pulses, and the right nozzle only had the last pulse. The three pulses used to create the drops were evenly-spaced in time, and each image was taken at the time where the pressure wave hit the opening of the nozzle.

Notice the extensions in the nozzle meniscus that happen after pulsing has finished, which are caused by the pressure waves. The first one occurs even before the ligament has separated. The meniscus bumps are larger on the nozzles that have fired twice or more, confirming that extra pressure has been applied thanks to previous pulses. By adjusting the pulse timing and visualizing your progress, you can make improvements to a waveform for a particular ink much more quickly.

The extra pulses aren’t only used for jetting larger drops. It is common to use a pre-pulse on the “off” data to tickle the nozzles, meaning that enough force is provided to keep the ink moving within the nozzle, but not eject a drop. Another application is using a post-pulse to cancel the meniscus oscillations, allowing you to increase the frequency without interference from the previous drop. The waveform below has many such features built in and is adapted from a Ricoh patent for a desktop printer.

So that concludes our introduction to waveforms, next up we will learn how to make a waveform from scratch or optimize an existing one for a particular ink.