Pros and Cons of Recirculating Printheads

Last Updated on June 25, 2024 by ImageXpert Team

Printheads that recirculate ink have been around for a while now and have been heavily adopted by the fast-growing ceramics market. But have you ever wondered why it is important for some applications and whether you should be considering it? After describing the differences in print heads, we look at some of those questions in this post and consider the pros and cons in terms of complexity versus technical advantage.

WHAT IS RECIRCULATION?

The concept of recirculating the ink is inherent to other types of digital print systems like CIJ, where the non-printing drops get recycled around the ink circuit to be used again. Since drop-on-demand heads don’t have these non-printed drops, the recirculation is internal to the heads themselves. There is a constant flow of ink in one side of the printhead and out the other.

ADVANTAGES OF RECIRCULATION

So why bother recirculating? The two biggest reasons are to combat settlement (ceramic inks or white inks) and latency (water/solvent inks). In the first case, the constant motion of the ink avoids the settlement and agglomeration of pigments that are denser than the ink. In the second, especially for faster-drying inks, the recirculation can help prevent drying in the nozzles due to evaporative losses.

There is also an advantage for inks that rely on being heated: temperature uniformity. If the ink is constantly moving, the entire system can be kept more uniformly heated, rather than having temperature fluctuations created by constantly changing printhead duty cycle. This can have a positive effect on cross-head uniformity.

When using an ink system with degassing capabilities, it is possible that the ink below the degasser could become less degassed whilst the system is idle. For longer periods of non-use, this can mean fresh ink needs to be purged through. If the ink is recirculated as part of the printer start-up process, then the stagnant ink can be passed though the degasser again and fresh ink fills the head. The only stagnant ink is the very small volume in the channels themselves.

All the considerations above apply to keeping the ink in prime jettable condition at all times, regardless of the chemistry or the length of the print pause.

DISADVANTAGES OF RECIRCULATION

The principle challenge of introducing recirculation is ink supply system complexity. As compared to a gravity-fed ink supply system, there is a greater number of pumps and pressure controls. Simply purging some ink from the head can become quite complicated!

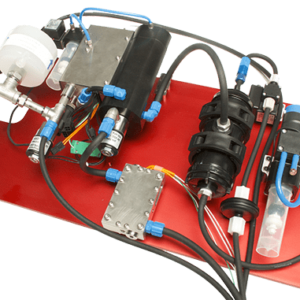

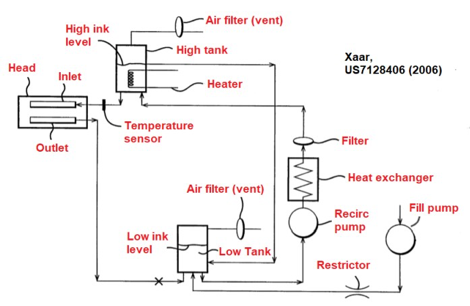

To give some idea, we show what an example ink system for recirculation involves, borrowing from a Xaar patent. In this scheme, the pressure into and out of the head are set by the height of the tanks. This is the simplest way of achieving recirculation but can be inconvenient in terms of locating the tank on a real printer. In practice, it is more common to use even more hardware to create a controlled vacuum on each tank.

The complications don’t stop there though, because constant ink flow can lead to added stress on the ink itself, especially in heated systems or where mechanical agitation of pumping can cause foam. Some pumps and inks don’t really like each other that much and continuously pumping the ink over and over can have negative side-effects if the materials used in each are not compatible.

Since many single pass inks rely on low surface tension, foaming can also be a big consideration. Quite a common failure point for recirculating ink systems is to get fluid into the vacuum lines, where it can wreak havoc with solenoid valve or o-rings that were not considered to be in the ink path. Good ink system design will assume this is going to happen sometime and do something to protect against it. Likewise, the ink itself can be tuned for low foaming, although sometimes with compromises.