Micro Dispenser Manufacturing

ImageXpert Partners

ImageXpert has a long history of drop analysis solutions for the industrial inkjet printing industry, where controlled deposition of pL-sized drops is essential for success. As the micro dispensing industry evolves and requires smaller, more precise drops of complex fluids, more and more precision dispenser manufacturers, as well as their customers, are turning to proven ImageXpert technology for help. Micro dispensing manufacturing is pushing the frontiers of jetting valve technology into applications such as electronics assembly, biomedical production, and life sciences research, as they chase their customers into the nanoliter and picoliter range. Ensuring that they can consistently deliver a drop with precise volume and position is a difficult problem and one that ImageXpert excels at solving.

Common Challenge: Acheiving Higher Precision

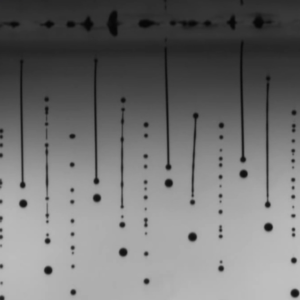

For many new applications, like dispensing into microwell arrays, complex electronics, or microneedle patches, the requirements for drop consistency and placement, across a widening range of materials, are higher than ever before. This higher standard requires complete optimization of the dispensing setup, and the company that is able to provide a complete solution to the customer, with an optimized combination of fluid, dispenser, and dispensing settings will be well positioned for these changes. JetXpert systems allow you to measure drop volume, velocity, trajectory, and detect the presence of satellites, giving you insight into how to adjust each of these parameters to improve them.

Critical Measurement: Dispensed Volume

For those in the pharmaceutical or biomedical micro dispenser manufacturing industries, ensuring that the exact amount of API (active pharmaceutical ingredients) is deposited each time is crucial. Measuring the volume of single drops in flight has many advantages over traditional methods like weighing stations because you are able to see the deviation from one drop to the next instead of an average across a large sample.

Learn How to Measure Volume With the JetXpert OEMCommon Challenge: Error Detection

Biomedical fluids, electronics, and other complex parts are expensive, meaning that producing failed parts often comes at a huge cost. ImageXpert’s inline measurement tools allow you to correct the issue while it is happening in production, saving time and material. In additional to drop-in-flight measurements that can detect dispensing inconsistencies, we have systems to study the products post-dispense, verifying that wells are successfully filled, printed electronic lines are continuous, and other quality assurance criteria are met.

Recommended Products for Micro Dispenser Manufacturing

- Inline JetXpert

- JetXpert 3D

- Dot Positioning

- Lab on Chip R&D and QA

- Metal Strip QA

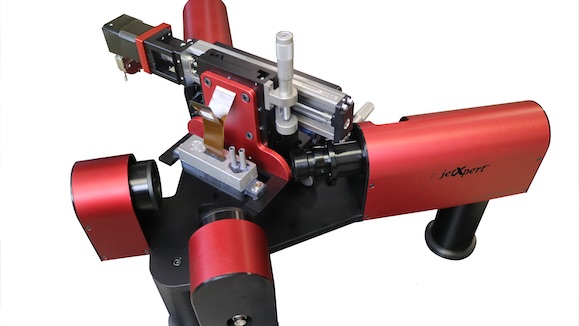

Inline JetXpert

An Inline Drop Analyzer Without Limits. With its unique angled design, the Inline JetXpert sits below the printhead instead of alongside it, eliminating printhead width constraints. Inspect an entire printhead array of any size with the world’s first inline drop analyzer.

Learn More

JetXpert 3D

Demanding applications call for extremely accurate drop size and placement. The JetXpert 3D uses dual cameras and optics to analyze a drop in orthogonal planes for full shape and trajectory analysis.

Learn More

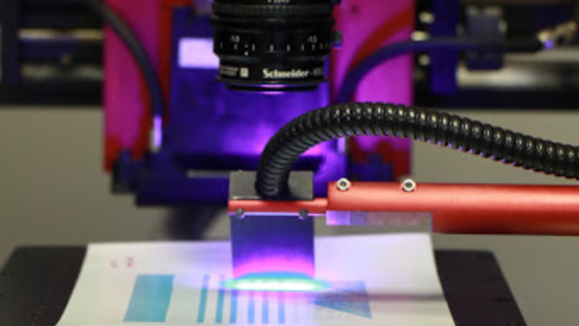

Dot Positioning

The most demanding inkjet applications require critical dot size, shape, and position accuracy with drops as small as 1 pL in size. Our Dot Positioning systems perform analysis with micron-level resolution, so you are able to clearly see the smallest drops and satellites and perform accurate measurements.

Learn More

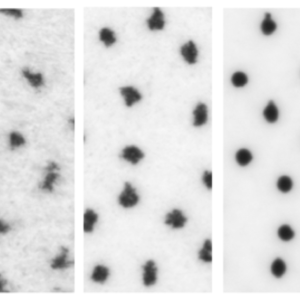

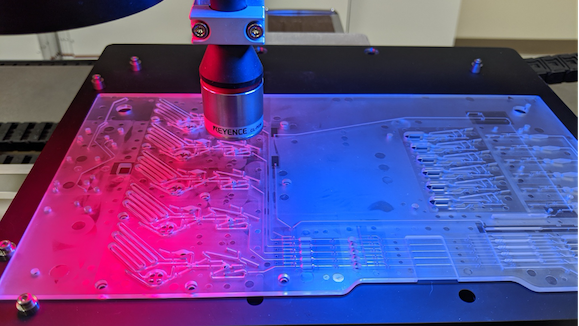

Lab on Chip R&D and QA

When our customer needed to redesign, optimize, and begin manufacturing a new lab on chip design as soon as possible, we provided the cutting edge measurement system they needed to get detailed measurements across the sample, at the press of a button

Learn More

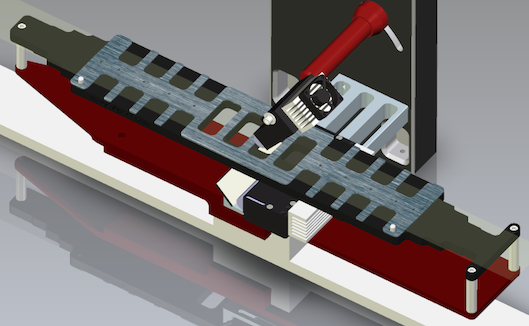

Metal Strip QA

We designed and delivered a high precision linescan imaging system capable of measuring the widths of metalized plastic strips to micron accuracy, and inspect for pinholes, in under 30 seconds — speeding R&D and later, QA. The system features custom optics, lighting, motion and camera control systems, and machine vision software application.

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for micro dispenser manufacturing, we’d love to hear from you.