A Look at PV Nano Cell’s Waveform Optimization Process for Sicrys™ Nano Silver Conductive Ink

Last Updated on September 8, 2021 by ImageXpert Team

Narrow printed patterns are an essential requirement for many printed electronics applications, as they allow smaller, flexible, and more efficient components to be produced. The width of a printed pattern is determined by the ink chemistry, ink interaction with the substrate, drop size, and printing technique. PV Nano Cell has developed a 5-dimensional printing technology (chemistry, width, length, thickness, and printing process) which optimizes all these factors in combination to get the desired results according to the application requirements. As part of this 5D technology, waveform optimization is performed to tune the drop size to the application needs while still keeping a stable and robust printing process. In cases where narrow patterns are required, the optimization is performed to achieve the smallest possible drops.

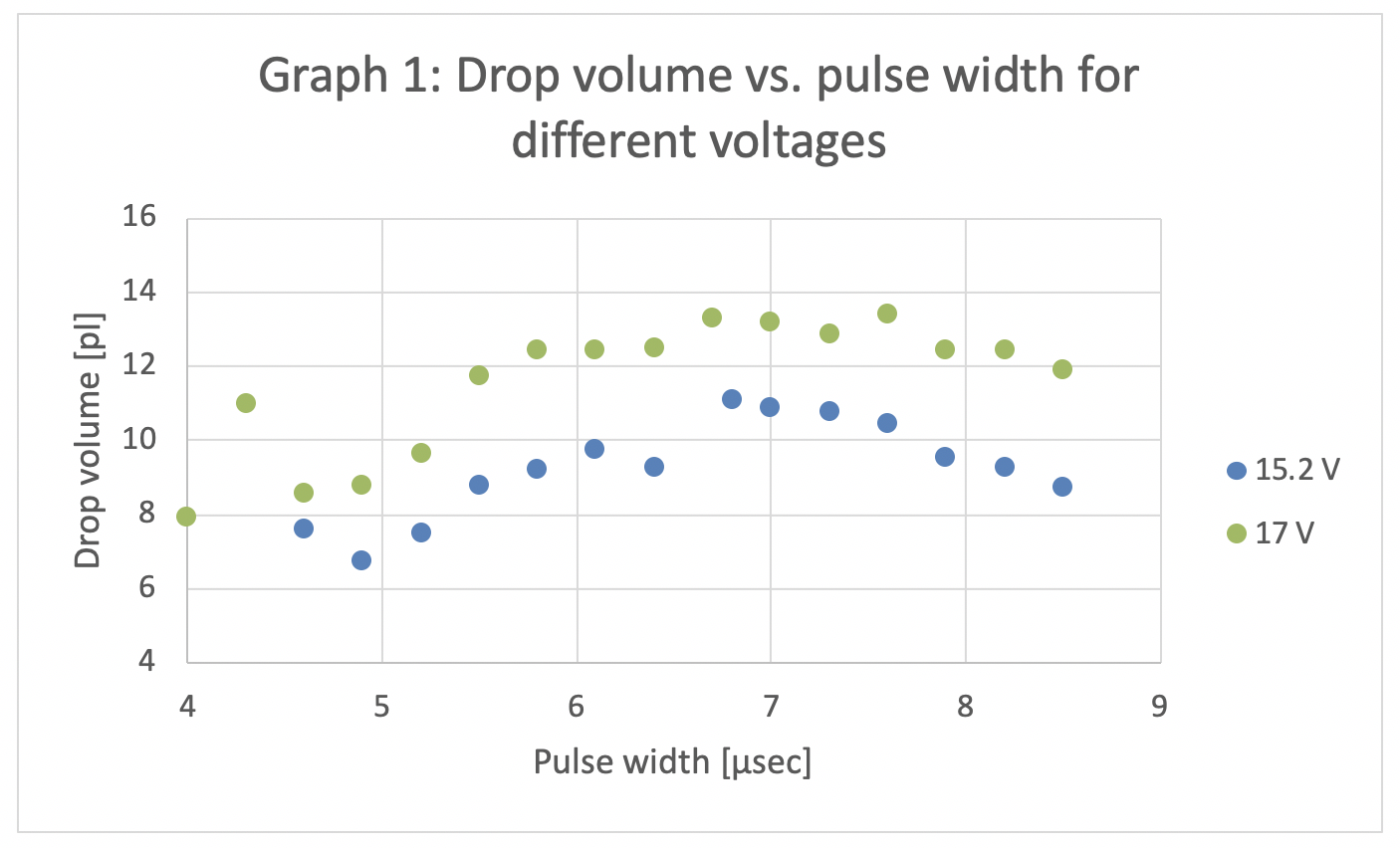

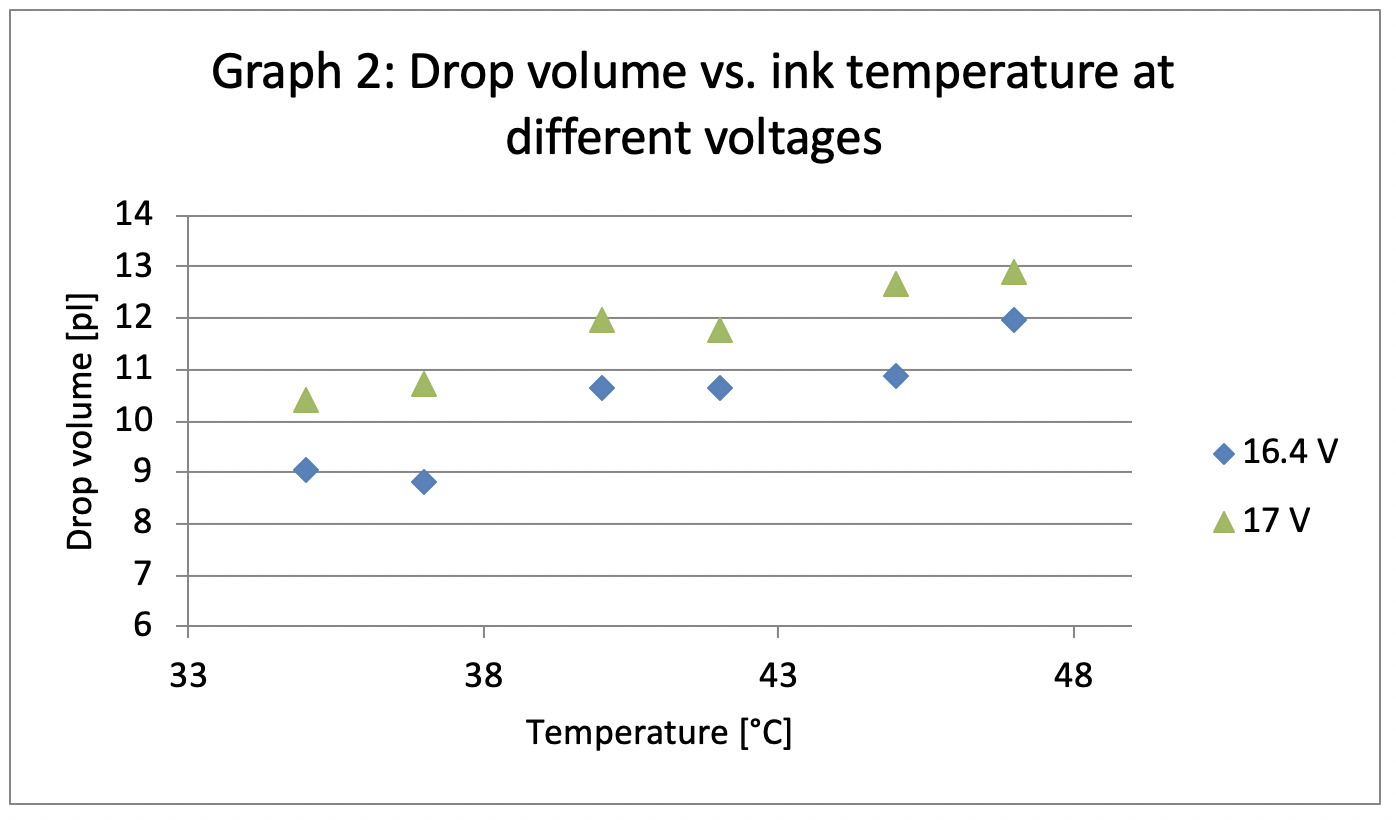

The waveform optimization process is designed around a very strict, systematic workflow focused on five main parameters: fluid viscosity, drop velocity, waveform pulse width, waveform pulse amplitude, and jetting frequency. The process begins by measuring fluid viscosities at different temperatures, which is especially important for conductive inks containing a high percentage of metal (typically 3% – 60% w/w). Our strategy is to maximize the fluid consistency with a narrow percentage of metal deviation and then adjust the ink temperature to match the viscosity needed for the application.

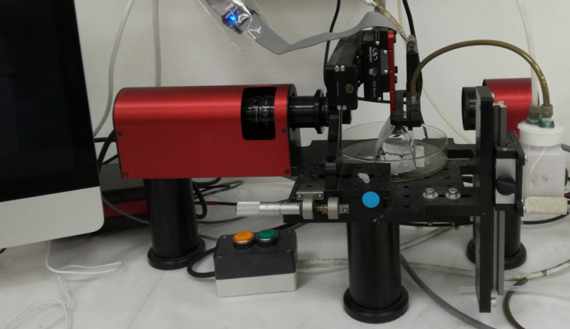

Next, the fluid is printed and drop velocity is measured for a range of pulse widths, pulse amplitudes, and jetting frequencies to ensure that the velocity falls within our established window of acceptable values. We use a JetXpert Dropwatching System for collecting the data, which is one of the best tools available to perform these optimization processes.

JetXpert Dropwatcher System used for collecting images and data

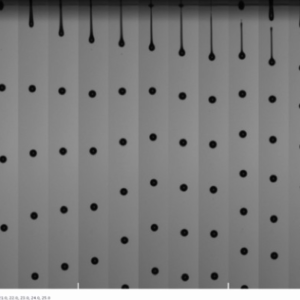

Drops of conductive ink as seen on the JetXpert Dropwatcher System

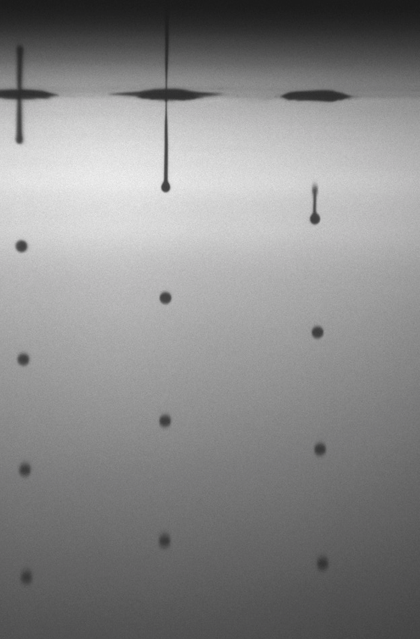

The next step of the procedure tests the jetting stability, the drop volume, and satellite formation across these same parameters. A combination of different parameters is tested to minimize the drop volume while maintaining a certain level of drop velocity, stability, and print speed.

KM1024iMHE printhead and Sicrys™ conductive ink, captured on a JetXpert

KM1024iMHE printhead and Sicrys™ conductive ink, captured on a JetXpert

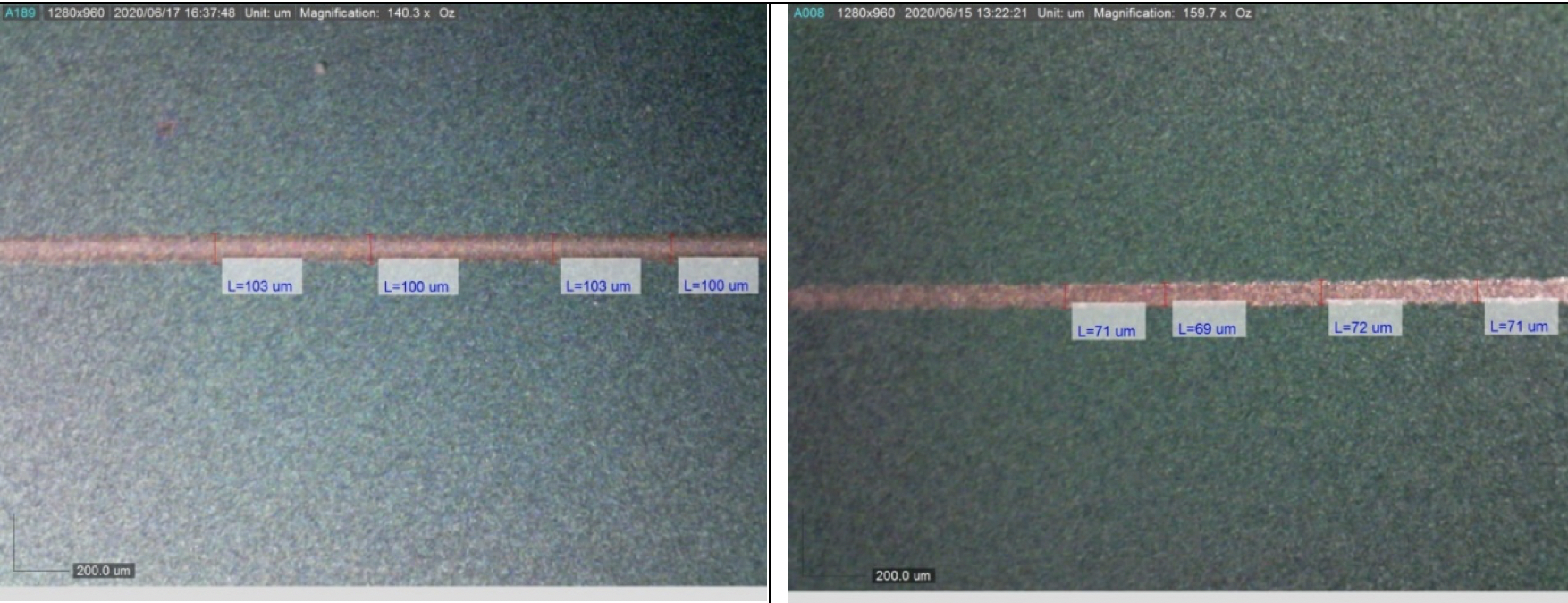

The impact of designing and tuning a waveform for a specific application can be quite impressive. In one project, we successfully reduced print width patterns from 100 µm to around 70 µm by performing this 5D printing optimization process.

Measuring Sicrys™ conductive pattern width before and after 5D optimization (100 µm before and 70 µm after)

You can see the final printed product here: