Printed Electronics

ImageXpert Partners

Producing electronic devices with inkjet printing is a fast-emerging technology with promising applications in flexible electronics, wearable electronics, solar panels, sensors, and OLED displays.

Inkjet printing offers several advantages over traditional contact methods of printing using masks:

- The production costs are substantially lower, especially for small batches, as the patterns are generated on-demand and there is virtually no wasted material.

- There is no limit to the size of the printed area, which allows for the production of large electronics like OLED displays.

- The non-contact nature of inkjet printing also means more substrate materials and shapes are available, with less risk of contamination.

Common Challenge: Extreme Precision

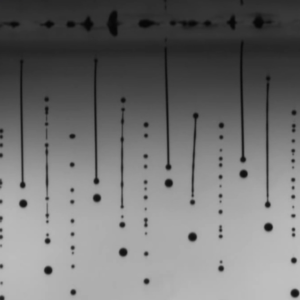

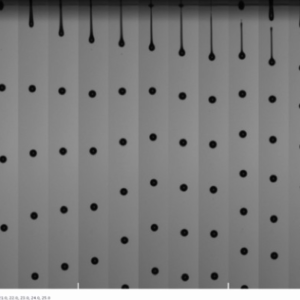

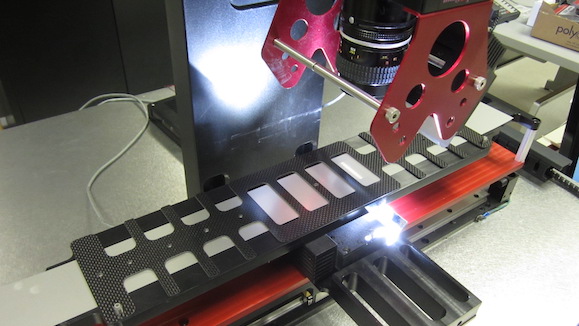

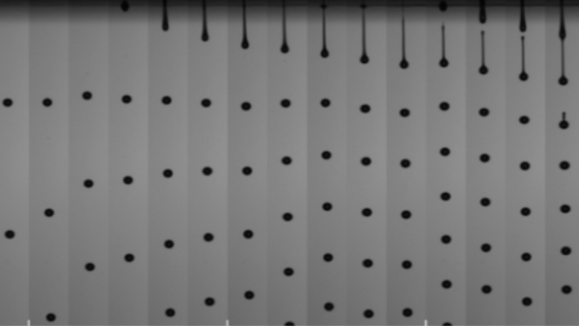

Most inkjet applications are somewhat forgiving to the presence of satellites, missing jets, and inconsistent dot size – but not printed electronics. All the jets need to fire properly, and a lot of material needs to be precisely deposited, in order for the printed lines to be conductive. Satellites in the wrong places run the risk of shorting the electronics. For this reason, dot positioning measurement systems are a perfect match for printed electronics developers. Analyzing each printed dot individually, checking for its size and positional accuracy, this is the level of precision required for success in this market. We’ve produced an all-in-one dropwatcher, sample printer, and dot positioning measurement system to help printed electronics developers optimize their printing process faster.

Critical Measurement: Inline Verification

Several aspects of a printed electronics production printer are hard to replicate on a standalone dropwatching system such as the clean-room environment or the electrostatic effects on the drops in flight. For this reason, once an ink is jettable, many companies want to move towards optimizing their jetting within the printer itself. The Inline JetXpert was specifically built to fit within your printer, so you can continue benefitting from dropwatching analysis even after you leave the lab.

Learn More About the Inline JetXpertCommon Challenge: Missing Jets

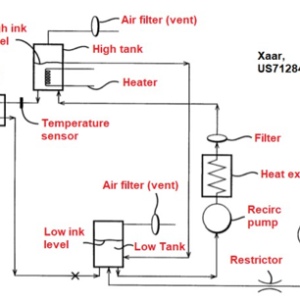

Another important factor to consider is the compatibility of the printhead with the materials that you plan to jet. The fluids used in printed electronics tend to contain large, dense particles, which means that keeping the nozzles on the printhead from getting clogged, scratched, or worn away is a unique challenge to be addressed. To combat this, we’ve seen that most of our customers in the printed electronics industry are experimenting with recirculating inkjet printheads, as this technology is well-established in other industries where fluid drying or clogging is common. Our customers are also using the NozzleXaminer Add-On for the JetXpert Dropwatcher to study the wear and tear of their fluid on the nozzles of the printhead. Rather than disassembling the system to inspect the printhead on a microscope, they can study the impact of the fluid formulation, particle size, and printhead lifespan on the nozzles while they are still in use.

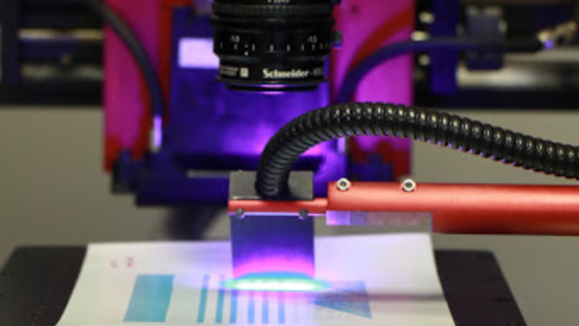

Critical Measurement: Part Inspection

The width, height, continuity, and other elements of the printed lines are the difference between a successful build and a failed part. Automated, optical inspection of printed electronics is important but challenging because the surfaces are often shiny, mirrored, or other difficult contrast scenarios. ImageXpert has the experience in a variety of electronics applications such as solar to design a system that makes these measurements possible.

See Custom SystemsCompanies exploring printed electronics are one of our fastest-growing customer segments, so if you’ve got questions about getting started using industrial inkjet technology in this groundbreaking industry, reach out to us and we will be happy to share our experience!

Printed Electronics Products

- Inline JetXpert

- XSweep

- Metal Strip QA

- NozzleXaminer

- Dot Positioning

Inline JetXpert

With its unique angled design, the Inline JetXpert sits below the printhead instead of alongside it, eliminating printhead width constraints. Inspect an entire printhead array of any size with the world’s first inline drop analyzer.

Learn More

XSweep

Make the process of waveform optimization more automated with XSweep. Simply specify which waveform parameter you want to adjust, like voltage or pulse width, and enter a range of values to test, and the software will automatically capture images and data for each one.

Learn More

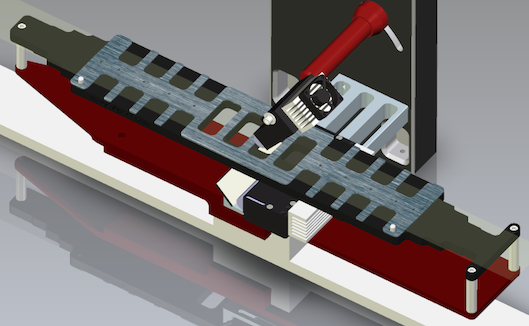

Metal Strip QA

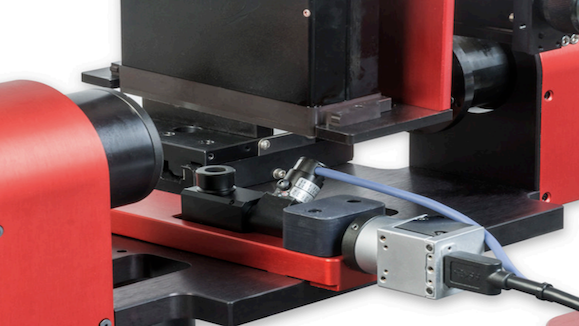

We designed and delivered a high precision linescan imaging system capable of measuring the widths of metalized plastic strips to micron accuracy, and inspect for pinholes, in under 30 seconds — speeding R&D and later, QA. The system features custom optics, lighting, motion and camera control systems, and machine vision software application.

Learn More

NozzleXaminer

A portable microscope that can be inserted underneath the printhead to quickly check for scratches, worn coatings, or debris on the fly. Diagnose the causes and understand the performance impact of damage to the nozzles or nozzle plate.

Learn More

Dot Positioning

The most demanding inkjet applications require critical dot size, shape, and position accuracy with drops as small as 1 pL in size. Our Dot Positioning systems perform analysis with micron-level resolution, so you are able to clearly see the smallest drops and satellites and perform accurate measurements.

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for printed electronics, we’d love to hear from you.