Coating/Adhesives

ImageXpert Partners

The global trend of producing things faster, with higher precision, and at lower cost has led many manufacturers to choose industrial inkjet printing and micro dispensing coatings and adhesives as part of their production process. Materials that used to be applied with techniques like spray coating, dip coating, or analog printing are now being jetted or dispensed. These methods offer more flexibility, finer control, and less wasted material. This presents opportunities for companies to develop coatings and pretreatments for use with inkjet inks, as well as jetting or micro dispensing coatings and adhesives directly. The adoption of inkjet printing into these applications on a variety of materials presents many material compatibility challenges, as well as opportunities for companies who can provide the treatments to make it possible.

Common Challenge: Real-World Testing

Companies developing pretreatments and coatings often struggle to understand how their material will perform in new applications due to the technical complexity of the inkjet process and the wide variety of inks, substrates, and printers on the market. Because they don’t have the means for testing in-house, many companies have to resort to sending new materials to be tested on customers’ equipment, starting a lengthy process that is difficult to support. Companies embracing inkjet are opting instead for building a testing system themselves, so they can evaluate new materials for compatibility with different applications before selling them. Using a JetXpert Print Station, they are able to print using the same printhead and ink as their customers, so they know exactly how their materials will react. This strategy allows for faster time to market, increased customer confidence in their product, and easier support and partnerships in the future.

Critical Measurement: Print Quality

The size, shape, color, absorbance, and drying time of the ink on the substrate all have an impact on the image quality / performance of the print and will change with the properties of the surface. The best way to systematically improve this process is through Print Quality analysis. Systems that measure Dot Positioning or Test Targets are designed to break down a printed image into several measurable tests, which can be used to optimize the substrate, pretreatment, and ink combination.

Learn How to Benefit from Print Quality MeasurementsCommon Challenge: Missing Jets

The fluids used in adhesive printing contain binder materials, which means that keeping the printhead from gluing itself shut is a unique challenge to be addressed. Minimizing missing jets is especially critical in this application because they can impact the structural integrity of the part. Other applications can rely on software tricks and nozzle compensation to accommodate small defects, but in adhesive printing all the nozzles need to work all the time. To combat this, we’ve seen that most of our customers in this industry are experimenting with recirculating inkjet printheads, as this technology is well-established in other industries where fluid drying or clogging is common. Along with recirculation, developers rely on printhead spitting and tickle pulses to help maximize the open time of the printhead.

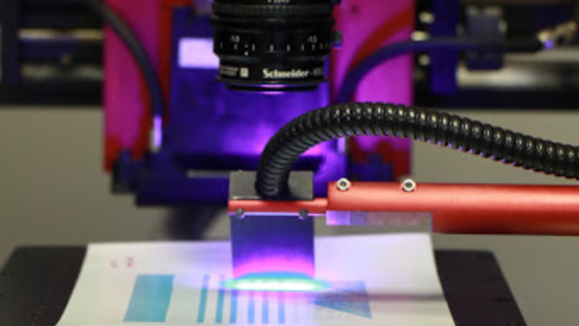

Critical Measurement: Drops-in-Flight

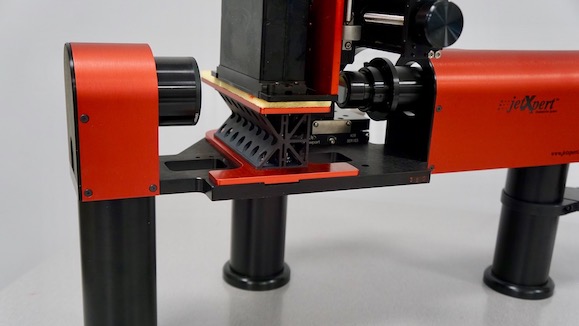

In the most high-precision applications like printed electronics, coatings, adhesives, and other materials must be jetted or dispensed directly. For these developers, ensuring that the right amount of material is jetted consistently and accurately is key. A JetXpert Dropwatcher can play a huge part in this process, with the ability to analyze the drop volume, velocity, and trajectory in flight.

Learn MoreRecommended Products for Coatings and Adhesives

- JetXpert Print Station

- Latency Sweep

- Capping Station

- Print Quality Analysis

- JetXpert Dropwatcher

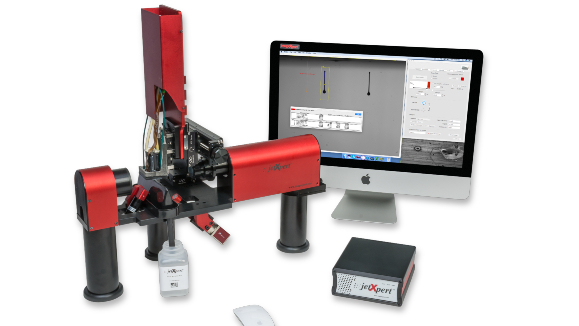

JetXpert Print Station

All-in-one dropwatching, sample printing, and print quality analysis for more efficient testing

Learn More

Latency Sweep

Instead of performing latency or open time testing with a stopwatch, easily determine the maximum idle time, or minimum recovery time, for your ink by testing different combinations automatically. Enter a list of idle times you want to test, and let the software take over by capturing images and data for each one.

Learn More

Capping Station

At the end of the day, developers often have to choose between the time consuming tasks of cleaning out their printhead now or recovering dried nozzles later. With the JetXpert Capping Station, you can skip both and quickly create an airtight seal around the nozzle plate to prevent the ink from drying.

Learn More

Print Quality Analysis

When you want to optimize your entire printing process, you need a way to evaluate your entire printing process. Print Quality tools analyze the end result, the printed image, so you can measure the output of hundreds of parameters at work in one easy test

Learn More

Inkjet and Dispensing Research Starts Here. The JetXpert uses top-of-the-line imaging technology to show you what’s happening inside your printer so you can improve it. Half micron resolution with a 8 million fps-equivalent exposure time means that drops, mist, and satellites are clearly visible, even ones smaller than 1pL in size. We built this system from the optics up, and it shows.

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for micro dispensing coatings, we’d love to hear from you.