Printhead Manufacturing

ImageXpert Partners

ImageXpert has roots in the inkjet printing industry that go back over 25 years. The earliest ImageXpert systems for measuring print quality were used by the founding companies of inkjet technology. At that time, inkjet printers were primarily used for printing on paper and were produced by only a handful of well-known companies such as HP, Epson, Canon, Brother, and the like. Today, ImageXpert is proud to continue serving the inkjet printhead manufacturing industry with systems trusted by every major manufacturer worldwide.

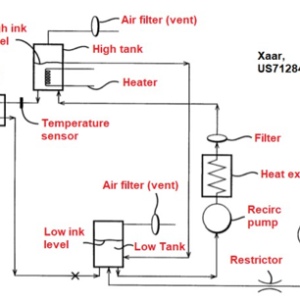

Common Challenge: Fluid Testing

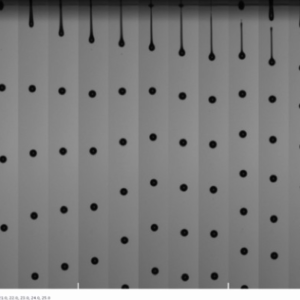

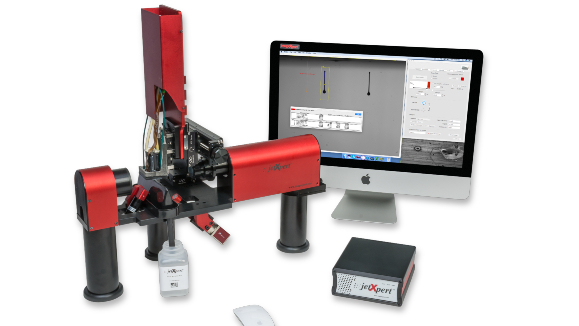

Testing and certifying customer inks and fluids is a major component of inkjet printhead manufacturing, and it can take a lot of time if it isn’t done with the right equipment. The JetXpert platform has tools for automatically measuring drop volume and velocity, identifying missing jets, frequency sweeping, performing open time testing, and all the other tests needed to evaluate a fluid, faster than ever before.

Critical Measurement: Waveform Optimization

Another role of printhead manufacturers is designing waveforms matched to a customers’ ink, which can be a long process if done manually. The XSweep Add-On for the JetXpert Dropwatcher allows you to automatically test a range of values for a particular waveform parameter, or a range of different waveforms, to find the right match quickly and more accurately.

See How XSweep WorksCommon Challenge: Benchmarking Printheads

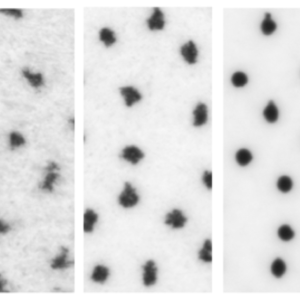

One hurdle during inkjet printhead manufacturing is benchmarking printheads to evaluate the impact of material, design, and manufacturing changes on the jetting performance. In our opinion, the ultimate test for evaluating printhead performance is dot positioning, and we’ve got the systems to prove it.

Read Our Article on Dot Positioning

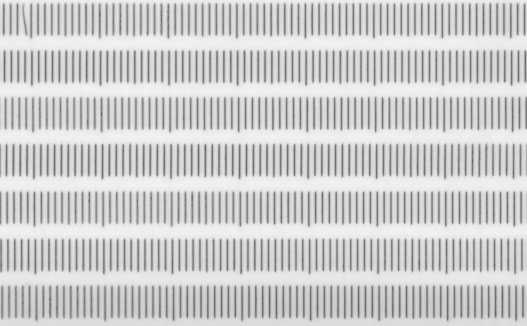

Critical Measurement: Manufacturing QA

Before delivering new printheads to customers, manufacturers need to evaluate that all of the nozzles are firing properly. To help automate this process, ImageXpert has tools that can identify misbehaving jets by examining a printed coupon.

View Nozzle Check ToolsRecommended Products for Inkjet Printhead Manufacturing

- JetXpert Dropwatcher

- XSweep

- Frequency Sweep

- Dot Positioning

- Coupon/ Nozzle Pattern Analysis

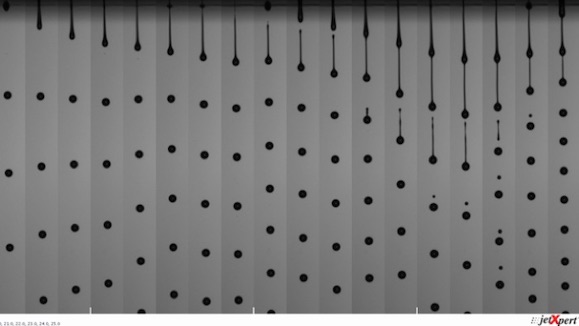

JetXpert Dropwatcher

Inkjet and Dispensing Research Starts Here. The JetXpert uses top-of-the-line imaging technology to show you what’s happening inside your printer so you can improve it. Half micron resolution with a 8 million fps-equivalent exposure time means that drops, mist, and satellites are clearly visible, even ones smaller than 1pL in size. We built this system from the optics up, and it shows.

Learn More

XSweep

Make the process of waveform optimization more automated with XSweep. Simply specify which waveform parameter you want to adjust, like voltage or pulse width, and enter a range of values to test, and the software will automatically capture images and data for each one.

Learn More

Frequency Sweep

Automatically ensure that your jetting is consistent at any printing speed. Frequency Sweep lets you enter a list of firing frequencies to test, and the software will automatically collect images and data for each one.

Learn More

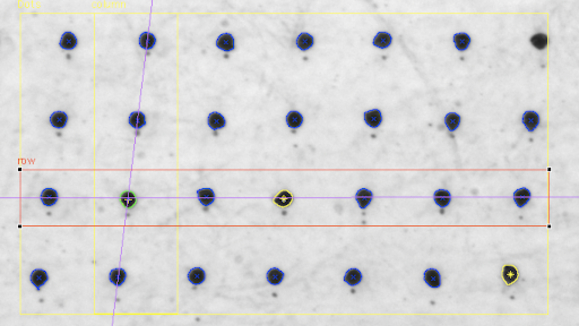

Dot Positioning

The most demanding inkjet applications require critical dot size, shape, and position accuracy with drops as small as 1 pL in size. Our Dot Positioning systems perform analysis with micron-level resolution, so you are able to clearly see the smallest drops and satellites and perform accurate measurements.

Learn More

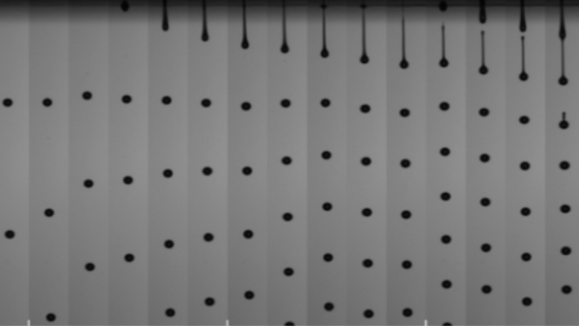

Coupon/ Nozzle Pattern analysis

Nozzle-by-nozzle inspection for assessing printhead health and alignment. Easily scan a printed pattern to check for missing jets, deviated lines, or other printhead failures.

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for inkjet printhead manufacturing, we’d love to hear from you.