Custom Molded / Machined Part Inspection

ImageXpert Partners

Production lines run on machine vision technology, with all sorts of parts being measured, sorted, and verified at high speeds for quality assurance. Certain parts are more challenging to inspect than others; parts that are reflective, transparent, extremely small, or oddly shaped can prove difficult to analyze accurately. This is where ImageXpert’s custom part inspection systems come in – measuring challenging parts with precision like no one else can.

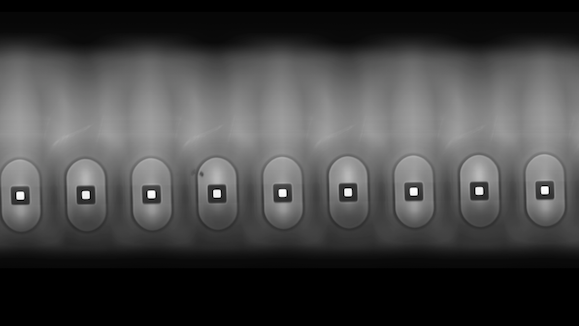

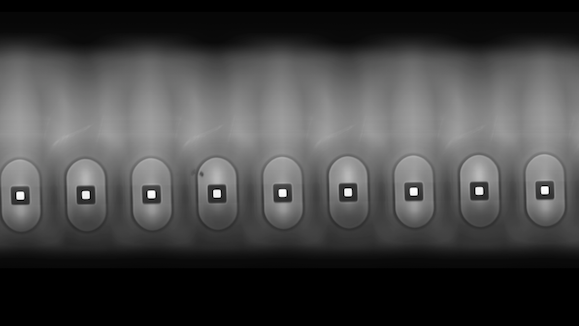

Cuvette Inspection

One of the largest medical cuvette manufacturers in the world wanted to speed up their quality assurance process. We delivered a high speed, non-contact system for verifying cuvette dimensional accuracy and integrity, reducing inspection times by a factor of 10.

Learn More

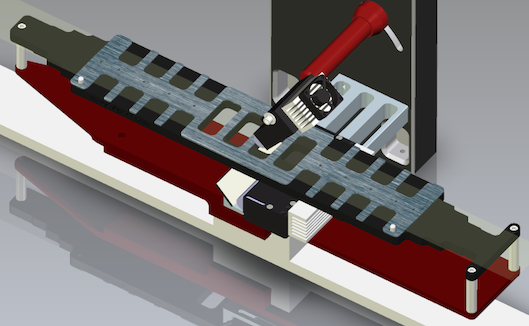

Metalized Strip QA

We designed and delivered a high precision linescan imaging system capable of measuring the widths of metalized plastic strips to micron accuracy, and inspect for pinholes, in under 30 seconds — speeding R&D and later, QA. The system features custom optics, lighting, motion and camera control systems, and machine vision software application.

How We Design Our Custom Part Inspection Systems

The design process starts with a deep dive into your specific application, with questions covering things like the measurements, tolerances, speed, and resolution. From there, we will experiment on some sample parts, testing different combinations of lighting and optics to capture images, along with configuring our advanced machine vision software to extract the measurements. Once we’ve found the right combination, we can integrate it into a complete solution with components like:

Cameras

Lasers

Lighting

Optics

Barcode Readers

Spectrophotometers

Motion Control

Part Handling

Software Analysis

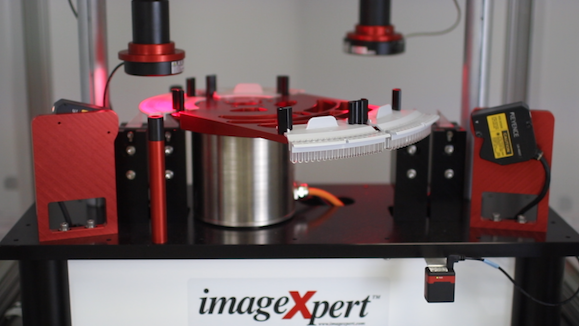

Nozzle Plate Inspection

Industrial inkjet printheads are impressive technology, requiring micron-level manufacturing precision. We built a system to inspect the nozzle plates with sub-micron resolution to help automate production for one of the top printhead manufacturers worldwide.

Learn MoreCustom Part Inspection Portfolio

- Cuvette Inspection

- Metalized Strip QA

- Nozzle Plate Inspection

- Lab on Chip R&D and QA

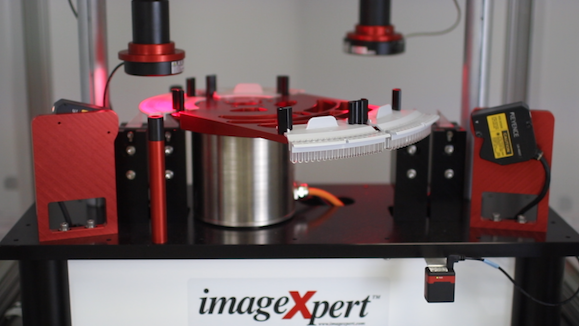

Cuvette Inspection

One of the largest medical cuvette manufacturers in the world wanted to speed up their quality assurance process. We delivered a high speed, non-contact system for verifying cuvette dimensional accuracy and integrity, reducing inspection times by a factor of 10.

Learn More

Metalized Strip QA

We designed and delivered a high precision linescan imaging system capable of measuring the widths of metalized plastic strips to micron accuracy, and inspect for pinholes, in under 30 seconds — speeding R&D and later, QA. The system features custom optics, lighting, motion and camera control systems, and machine vision software application.

Learn More

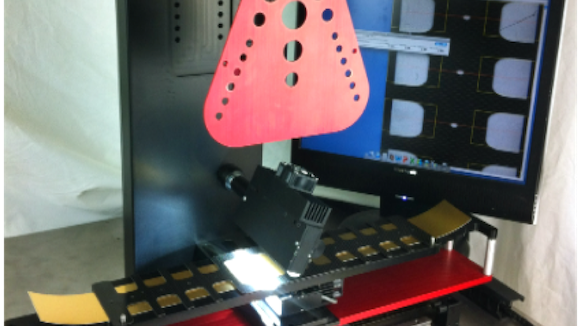

Nozzle Plate Inspection

Industrial inkjet printheads are impressive technology, requiring micron-level manufacturing precision. We built a system to inspect the nozzle plates with sub-micron resolution to help automate production for one of the top printhead manufacturers worldwide.

Learn More

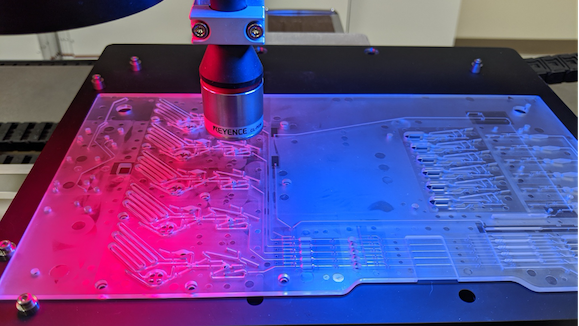

Lab on Chip R&D and QA

When our customer needed to redesign, optimize, and begin manufacturing a new lab on chip design as soon as possible, we provided the cutting edge measurement system they needed to get detailed measurements across the sample, at the press of a button

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for custom part inspection, we’d love to hear from you.