Biomedical Printing and Manufacturing

ImageXpert Partners

ImageXpert has partnered with companies from all facets of biotechnology and healthcare, from companies doing 3D biomedical printing with inkjet or microdispenser technology, to manufacturers of medical and healthcare products. Regardless of the application, these companies come to ImageXpert for one reason: accurate measurements. Whether you are dispensing pharmaceuticals into a microneedle array or manufacturing cuvettes, when someone’s health is at stake, microns matter.

Common Challenge: High-Precision Application

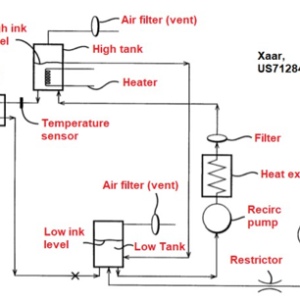

The biomedical printing and dispensing industry is calling for smaller and denser printed arrays for projects like microneedle patches, microwell arrays, or synthetic biology applications. Tools that analyze the drops in flight like the JetXpert OEM allow developers to optimize the fluid formulation or dispensing parameters to reach higher levels of drop volume and placement precision.

Critical Measurement: Drop Volume

For those in the pharmaceutical microdispensing or 3D biomedical printing industries, ensuring that the exact amount of API (active pharmaceutical ingredients) is deposited each time is crucial. Measuring the volume of single drops in flight has many advantages over traditional methods like weighing stations because you are able to see the deviation from one drop to the next instead of an average across a large sample.

Learn MoreCommon Challenge: Error Detection

Biomedical materials printed for pharmaceutical pills, beads, and fluids are expensive, meaning that producing failed parts often comes at a huge cost. ImageXpert’s inline measurement tools allow you to correct the issue while it is happening in production, saving time and material. In additional to drop-in-flight measurements that can detect dispensing inconsistencies, we have systems to study the products post-dispense, verifying that wells are successfully filled, printed parts are the right size, and the materials contain no debris.

Critical Measurement: Manufacturing QA

Medical and pharmaceutical component manufacturers also benefit from the powerful machine vision capabilities that we put into our custom systems, which allow us to capture images and measurements of parts and features that most other companies can’t. We use non-contact machine vision for part inspection, checking tolerances on anything from cuvettes to inhalers, which is often faster and more accurate than ever thought possible.

View Custom SystemsBiomedical Products

- Lab on Chip R&D and QA

- JetXpert OEM

- JetXpert 3D

- Cuvette Inspection

- Dot Positioning

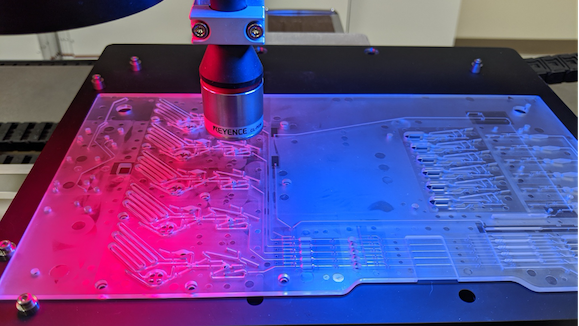

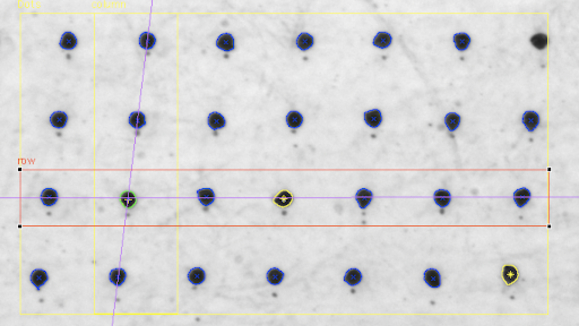

Lab on Chip R&D and QA

When our customer needed to redesign, optimize, and begin manufacturing a new lab on chip design as soon as possible, we provided the cutting edge measurement system they needed to get detailed measurements across the sample, at the press of a button

Learn More

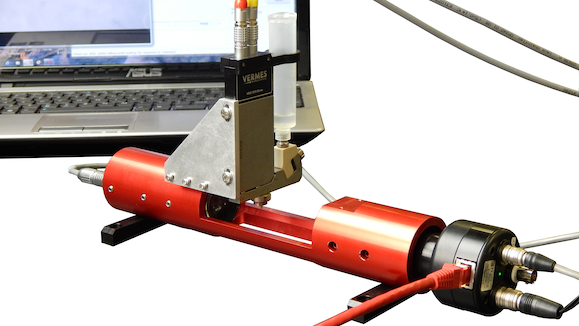

JetXpert OEM

Inline drop measurement built to fit your printer or microdispensing platform

Learn More

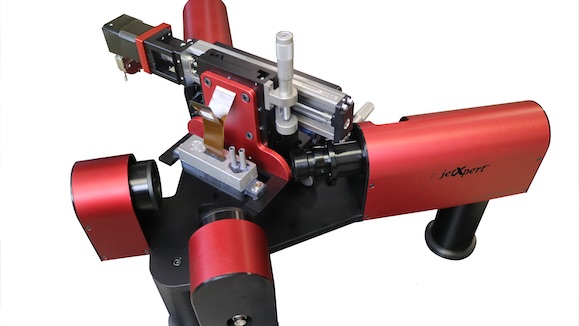

JetXpert 3D

Demanding applications call for extremely accurate drop size and placement. The JetXpert 3D uses dual cameras and optics to analyze a drop in orthogonal planes for full shape and trajectory analysis.

Learn More

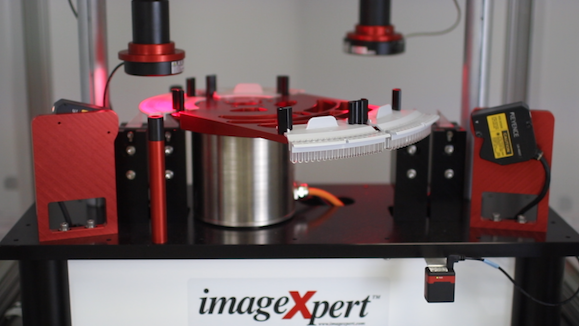

Cuvette Inspection

One of the largest medical cuvette manufacturers in the world wanted to speed up their quality assurance process. We delivered a high speed, non-contact system for verifying cuvette dimensional accuracy and integrity, reducing inspection times by a factor of 10.

Learn More

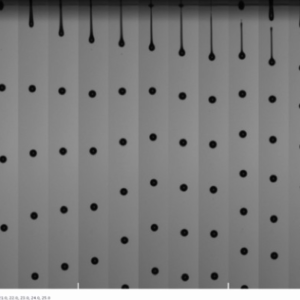

Dot Positioning

The most demanding inkjet applications require critical dot size, shape, and position accuracy with drops as small as 1 pL in size. Our Dot Positioning systems perform analysis with micron-level resolution, so you are able to clearly see the smallest drops and satellites and perform accurate measurements.

Learn MoreWhether you are looking for a quote, demo, or would like more information on a system for biomedical printing, we’d love to hear from you.