JetXpert Drop Analysis

Drop Visualization

Our industry-leading imaging technology allows you to see what’s happening inside your printer so you can improve it. Study drop-to-drop and nozzle-to-nozzle consistency, satellite formation, wetting, and more.

Lights, Camera, Action

By pairing a high speed strobe light with a high magnification camera and synchronizing them with the printhead or microdispenser firing, a JetXpert Dropwatcher is able to capture clear images of single drops in flight

How It WorksNumbers Are Fundamental

JetXpert can measure drop volume, drop shape, drop velocity and more, so you always know you are moving in the right direction. Drop analysis is automatic and accurate, whether your drops are one picoliter or one milliliter

One Size Fits All

JetXpert Dropwatchers work with any industrial inkjet printhead or dispenser. Whether you want to use your own equipment, match your customers’, or experiment with new ones, JetXpert can handle anything you throw at it.

Products

- JetXpert Dropwatcher

- JetXpert Jr

- JetXpert Inline

- JetXpert 3D

- Dropwatcher Add-Ons

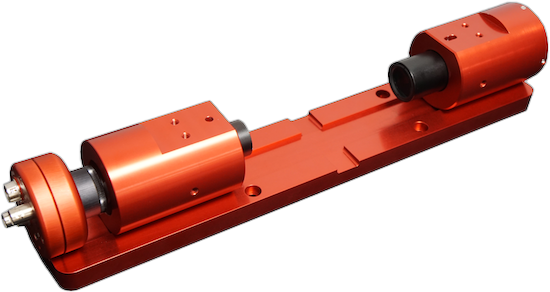

JetXpert Dropwatcher

The original R&D workhorse with all the bells and whistles, and over a decade of experience in labs

Learn More

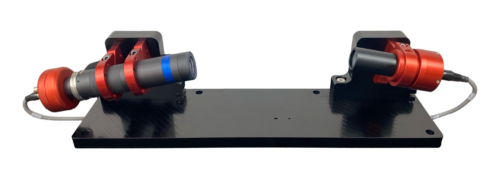

JetXpert Jr

A compact dropwatcher that fits any budget, built for integrating into your own test rigs or production printers

Learn More

JetXpert Inline

A dropwatcher with a unique angled design, allowing you to analyze large printhead arrays that won’t fit in other dropwatchers

Learn More

JetXpert 3D

Analyze a drop’s flightpath in three dimensions, when trajectory and volume accuracy are critical

Learn More

Dropwatcher Add-Ons

Enhance your JetXpert Dropwatcher with hardware and software upgrades. Add superpowers like additional cameras, automation, and other accessories.

Learn MoreNot Sure Where to Start? Let Our Team Guide You

Why Drop Analysis?

Industrial inkjet printing and microdispensing are extremely complex chemical, rheological, and mechanical processes with dozens and dozens of variables that can impact the quality of the produced part. Much of the operation is invisible to the eye, making it hard to improve the process systematically without simply guessing and checking. Drop analysis systems such as the JetXpert give developers a glimpse into what is happening inside their machines, allowing them to optimize their setup much more efficiently. Think of a drop watcher like the microscope-equivalent for industrial inkjet or microdispensing.

Drop analysis systems can also speed up inkjet and micro dispensing development by streamlining and automating routine tasks. They operate with small volumes of fluid that are easily swapped, unlike full industrial printers, so what used to take an entire day can be done in minutes. They are versatile, so if you decide to work with multiple printheads and dispensers, they can be swapped back and forth easily on one device in minutes. You can leave the system jetting or dispensing and return later to find a full report of images and data on missing jets, drop volume variation, and other important criteria. There are even tools to automatically optimize open time, waveforms, and more. Doing development on a system specifically built for R&D means you can get more done in less time.

Drop analyzers also play an important role in production quality control. Drop volume measurements of single drops in flight are among the most accurate methods of determining dispensed volume, because they can account for satellites, evaporation, missing jets and more in real time. The dropwatcher can also detect missing or deviated jets, to help improve maintenance procedures and intervals.

Whether you are looking for a quote, demo, or training on any of our drop analysis systems, we’d love to hear from you.