Actega Transitions from Analog to Digital Printing to Capitalize on Opportunity in Packaging Market

Last Updated on January 5, 2021 by ImageXpert Team

Who is ACTEGA?

ACTEGA develops, produces and distributes specialty coatings, inks, adhesives and sealing compounds with a focus on the packaging, graphic arts and medical industry. With production facilities in Europe, North and South America and China, we can react flexibly to customer requirements and provide technically advanced product solutions. Legally compliant products, specially tailored to the high safety standards of the food, pharmaceutical, tobacco and toy industries, determine our innovation roadmap and activities. ACTEGA is headquartered in Wesel, Germany and is a division of the internationally operating specialty chemicals group ALTANA. ACTEGA’s Aqueous Inkjet development team is based in Lehrte, Germany, near Hannover.

Why Did ACTEGA Pursue Industrial Inkjet?

ACTEGA is a leading supplier of consumables for flexo printing for the packaging market and recognized that digital print had a strong increase in penetration of this market. The packaging print market is in a heavy transition phase based on new market demands that could be met best with new technologies and digital printing. ACTEGA wants to seize this opportunity to hold a leading position for consumables for inkjet printing in the packaging printing market, expanding the robustness of their product portfolio. With this in mind, ACTEGA started the development of inkjet fluids (primer, ink, overprint varnish) for piezo drop-on-demand applications in 2015 with a focus on water-based fluids for non-absorbent substrates. The core target market is the world of packaging printing, but the technology fits the requirements of several particular markets and applications that could prove to be attractive business opportunities for growth.

When Did ACTEGA First Meet ImageXpert?

ImageXpert was our partner from the very beginning of our inkjet development journey. ImageXpert is the supplier with the longest history and experience in the inkjet area, and we were not just looking for a device but also to learn from their experience. The right equipment is very important when developing inkjet fluids, but also to have partners who give the best service and support available on the market.

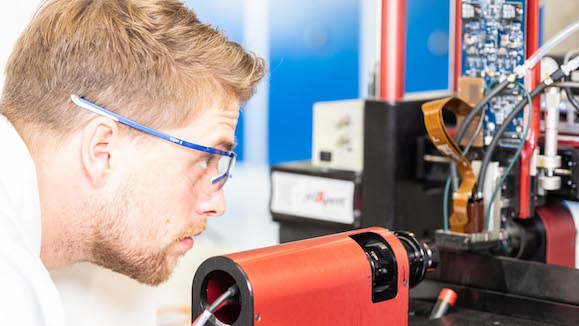

Why Did Actega Choose a JetXpert and JetXpert Print Station?

Inkjet technology is an emerging, very complex technology compared to the flexo or offset world. Unlike analog printing, a new inkjet fluid will not be tested right away on an existing customer installation, so developers have to replicate a wide range of applications in-house and develop a robust ink to handle them. The right drop formation is crucial for the success of an inkjet fluid, so the ability for the fluid chemist to observe what their fluid is doing in the jetting process is extremely valuable. This observation delivers hints on how to adjust a formulation in the right way. With the JetXpert and JetXpert Print Station, we were able to build a test station for our fluids that allowed us to view the drop formation and optimize our jetting process, so we know how the fluid will perform in our customers’ printing process.

How Has the Pursuit of Inkjet Been Going for ACTEGA?

Through our R&D efforts, ACTEGA has learned that inkjet is a very complex technology that requires complex consumables as well. This combined with the requirements of the packaging printing industry regarding fluid robustness and compliance with regulations creates a very challenging task that is completely different from what the analog printing consumable industry is used to. We’ve also learned that in addition to the technical differences between digital and analog, the entire business model of digital printing requires a different approach. Just buying a digital printing machine is not disruptive. Despite the technical and business complexity, ACTEGA sees many opportunities for commercial success. We now have a portfolio of water-based prototype fluids that are compliant with regulations for indirect food contact. These fluids perform well on a broad range of substrates from film to paper and board, which opens up new, exciting markets for our package of primer, ink, and varnish.

How Has the Experience With ImageXpert Been?

The ImageXpert equipment supported our fluid development strongly in a positive way. Like with any other high-tech equipment, there is a lot to learn to utilize the equipment to the level that it is made for, but ImageXpert supports us in a very good way. They’ve taken the complexity of the inkjet process and made it manageable for our team, and we continue to partner with them on our new ventures.