Decorative Surfaces

ImageXpertのパートナー

Transitioning from analog to digital print production is revolutionizing how the decorative industry is producing wallpaper, tiles, laminates, flooring, and more. By printing directly onto the surface with inkjet technology, manufacturers can streamline production, minimize wasted material, and operate in a more eco-friendly way. Small production batches are cost-effective with inkjet, allowing for customized patterns, reduced inventory, and faster design changes. By providing the tools needed to evaluate and then optimize inkjet printing in R&D, ImageXpert is working together with leaders in the decorative industry to accelerate the adoption of this game changing technology

Common Challenge: Color Matching and Consistency

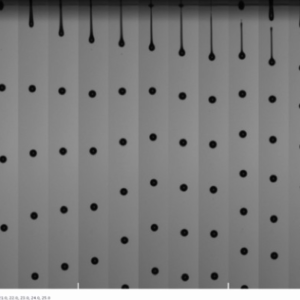

The human eye is incredible at detecting subtle differences in color or pattern, providing a challenge for manufacturers who need to decorate large amounts of building materials in a consistent way. Since images printed with inkjet are made up of dots, the size and placement consistency of those dots impact the color and uniformity of the printed pattern. JetXpert products help you study and improve the consistency of the printing all the way from the moment the drop leaves the printhead until it has been dried on the substrate. The JetXpert Dropwatcher allows you to measure drop volume, velocity, and more of the drops in flight, providing insight into how to optimize their uniformity. A JetXpert Print Station is an all-in-one system for analyzing jetted drops in flight and on the surface of the sample, custom-built for your substrate and ink. After the sample is printed, an integrated inspection system can analyze the print quality by studying dot size and placement, color uniformity, missing jets, and more.

The Importance of Ink Formulation

For those in the decorative surfaces industry, ensuring the durability of your product is especially critical. Product should not fade from UV exposure, textiles must last numerous wash and dry cycles, and flooring and furniture needs to survive scuffing. In order to achieve these ends, robust additives are often added to inks, which further complicates ink formulation. Finding the right printheads, waveforms, and processes to handle these challenging fluids is no small task – which is where the JetXpert Dropwatcher can help!

Learn More About the JetXpert DropwatcherCommon Challenge: Drop – Substrate Interaction

Achieving sharp lines and consistent colors is necessary for creating aesthetic products, which can be challenging on substrates not built primarily for printing. Nonporous / nonabsorbent substrates can cause ink to move around on the surface and produce blurry images. Substrates that are too absorbent can require large amounts of ink and still not achieve the desired color. Additives and pretreatments can help prepare the substrate to better accept ink, reducing ink consumption and improving performance along the way.

Recommended Products for Decorative Surfaces Manufacturing

- JetXpert液滴観測装置

- JetXpertプリントステーション

- Industrial Scanner

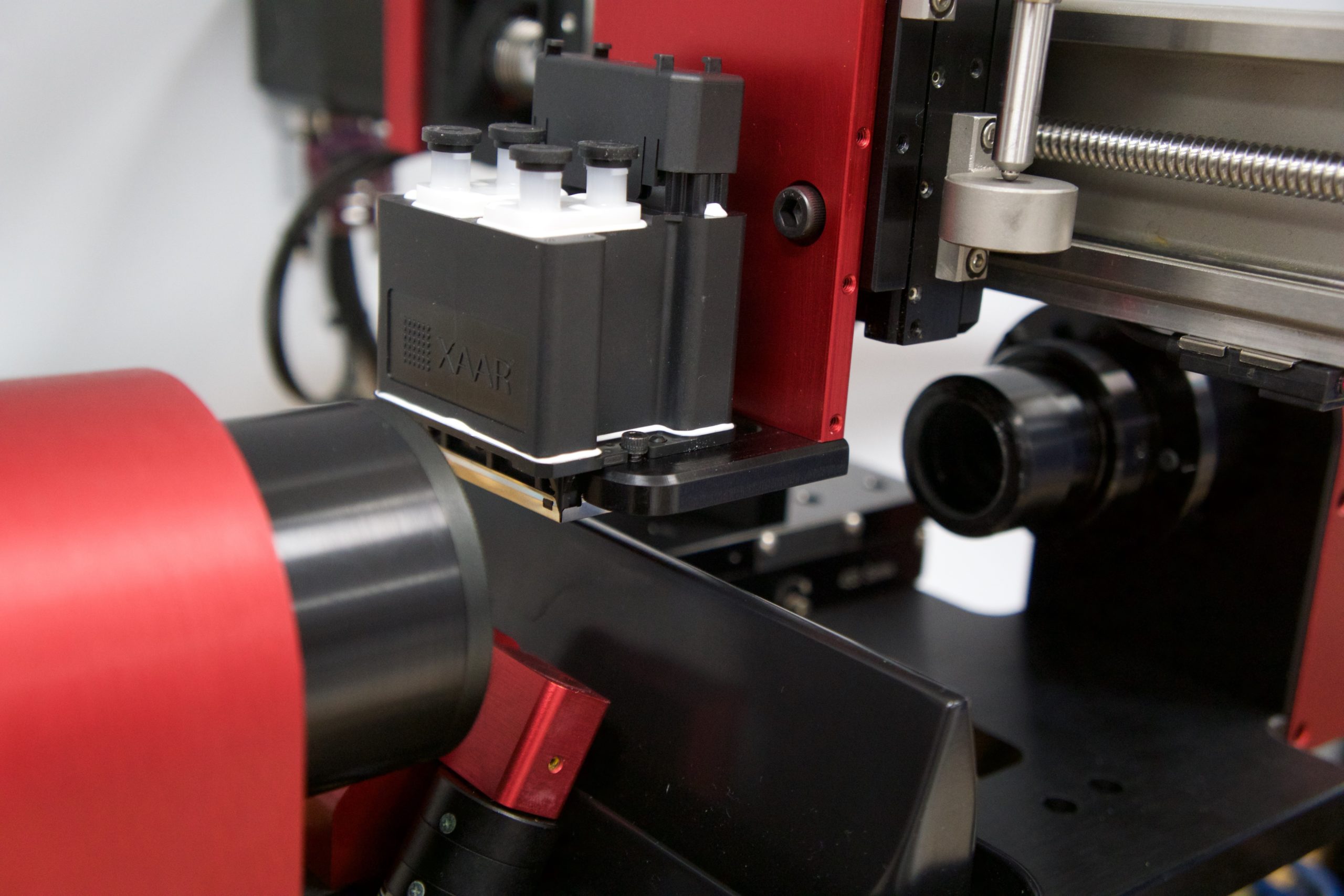

JetXpert液滴観測装置

The JetXpert Dropwatcher is a R&D tool designed to accelerate research and development. With the top-of-the-line ability to visualize drops, mist, and satellites, the JetXpert is also able to provide accurate measurements of drop volume, shape, and velocity. Functionalities include waveform optimization, nozzle-to-nozzle consistency checks, sustainability testing, among others.

詳細はこちら

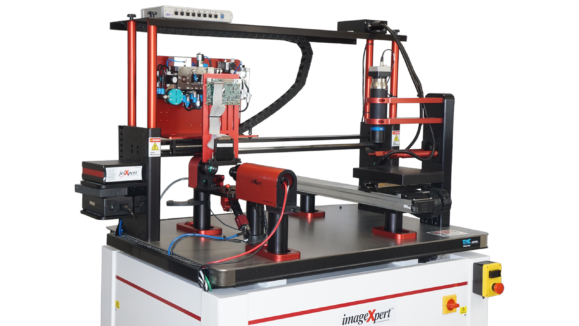

JetXpertプリントステーション

The JetXpert Print Station is the all-in-one tool you need for more efficient testing. With the ability to seamlessly switch between dropwatching, sample printing, and print quality testing, the JetXpert Print Station optimizes your process with more efficient testing.

詳細はこちら

Industrial Scanner

ImageXpert’s Industrial Scanner is built for print quality analysis of large area substrates. The scanners can be used to evaluate the end result and by extension the print process, allowing you to optimize your R&D and Production processes.

詳細はこちらWhether you are looking for a quote, demo, or would like more information on a system for decorative surfaces, we’d love to hear from you.