Reducing Missing Jets Through Proper Printer Maintenance

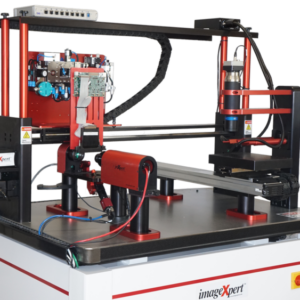

Whether you are in the R&D lab or the production floor, if you are working with inkjet, you are fighting against missing jets. We’ve covered a lot of the ink formulation and jetting-related causes for missing jets, but in this article we turn towards the printer itself and how it may be contributing to them. For that, we turned to Luc Van Damme, the founder of LVD Inkjet Services. With over a decade of experience as a service engineer for Dainippon Screen and Ricoh, he knows a lot about the design and maintenance tricks needed to keep a printer running smoothly. He was kind enough to share some of his knowledge and experience with us to teach us how to get the most out of our inkjet printers by understanding and reducing common causes for missing jets in production.

Missing Jets After Overnight Idle

One of the most commonly found issues in production printer maintenance is failure to start all of the nozzles jetting properly, especially for the first run of the day. This phenomenon is known by many terms in the industry, from “open time” to “decap” to “latency”, and it describes the failure of the printhead to jet properly after sitting idle for an extended period of time. The most common cause of this phenomenon is that the carrier fluid of the ink in the nozzle evaporates over time as it is in contact with the air. In some cases, it evaporates enough to modify the jetting behavior, in some cases, the ink completely dries in the nozzle.

Production printers have several built-in mechanisms to combat this evaporation and the primary one for overnight idles is a capping station. This is a small tray with a raised gasket that can be pressed up against the nozzle plate of the printhead to form an airtight chamber. When the printer is off, the printheads are moving to a capping position and sealed off from air. Over time, dried ink and other debris can build up on the nozzle plate or the capping station, preventing the gasket from making an airtight seal and allowing ink in the nozzles to evaporate. Keeping these components clean is critical, as you can see below. The gasket on the left came from a printer experiencing frequent ink drying problems; after it was cleaned (on the right), the problems went away!

Missing Jets from Dust and Debris

An often overlooked factor in the reliability of the jetting is the cleanliness of the substrate before it enters the printer. Large amounts of material move past the printhead at high speeds, so even small amounts of released dust and debris can build up on the printhead with enough time. For this reason, it’s recommended to install a web cleaning system at the entrance of the printer, which is often a brush that sweeps debris from the substrate into a filter as it passes by. Maintenance of this system is often overlooked, as the filters will become blocked (causing overheating errors) or the brushes wear out over time.

The left side of the brush is the used side (worn out) and the right side shows the unused portion (fresh)

Other systems you might encounter for cleaning the substrates can use compressed air or an adhesive roller instead of brushes. If you notice that the first rows of printheads are the ones with the most missing jets and least reliable, check to see if the dust is missing the cleaning system and hitting them instead!

メーリングリストに登録

Missing Jets Due to Clogged Filters

It is important that your ink supply system has multiple fluid filters installed in order to trap debris from the ink before it reaches the printhead and causes permanent damage, but these filters must be closely monitored or they can be responsible for another problem. If the filters on your ink supply system become blocked, the ink supply might have difficulty providing enough fluid to keep the printhead running smoothly. It may take a while for this problem to manifest after a maintenance purge because some fluid is stored in subtanks or inside the printhead itself, so test prints may look normal. However, if the fluid is not able to be replenished fast enough, then the nozzles will begin to drop out rather quickly in production once the residual fluid is used up. If you find that nozzles drop out quickly at high speed, high coverage production scenarios, changing the fluid filters is a quick potential solution.

Keeping Nozzles Activated for Long Runs

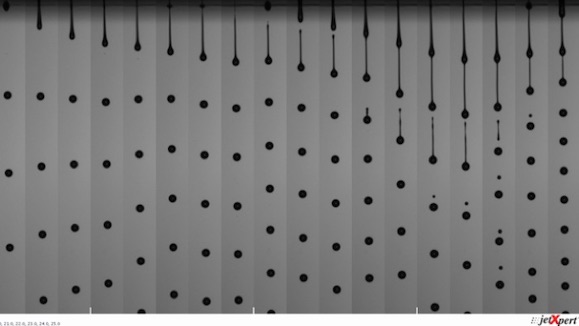

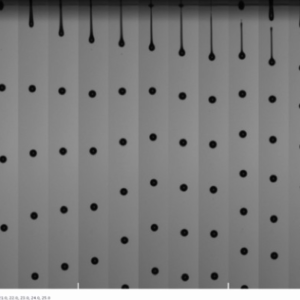

Depending on the pattern being printed, some jets may be firing more frequently than others, so keeping the less used nozzles primed and ready to go is another important task. Three common ways to do this are flushing lines, star patterns, and tickle pulses.

Flushing Lines are a simplistic solution to this problem. These printed lines are inserted before or after a printout and are designed to fire all of the nozzles to keep them active and “reset” them. These patterns will contain all of the colors and extend across the full width of the web to ensure that every nozzle is activated. These lines are then cut off and removed from the printed product.

Star Patterns use the same concept but in a more elegant way. All of the nozzles are kept activated by adding random patterns (stars) in the background of the print. These patterns are designed to randomly activate all the nozzles in such a way that the dots are not noticeable, so you can constantly keep activating the nozzles without a break in the print.

The waveform being sent to the printhead consists of pulses that are usually designed to eject a drop; however, a special pulse called a Tickle Pulse might also be used. These pulses do not have enough force behind them to eject a drop; just enough to keep the ink moving inside of the nozzle. If the fluid in the nozzle is constantly moving, this can help slow drying effects and particle coagulation.

Learn More About Waveform Optimization

Our article gives you step-by-step instructions with examples for optimizing pulse shape, timing, and tickle pulses

Read ArticleGood Maintenance Practices

A few simple techniques for printhead maintenance go a long way in extending the life of your printheads and printer. Small daily maintenance procedures are better than large weekly ones when it comes to printer uptime and cost, so it is good practice to print a daily test chart that checks for jetouts and clean the missing jets even if you do not necessarily need them that day.

The surface of the printhead collects all sorts of debris and ink but nothing a diligent cleaning regiment can’t handle. Start with the right cleaning solution as recommended by the manufacturer, whether it is distilled water, the ink without the pigment in it, or something stronger. Wet a lint free cloth with the solution and roll it up like a cigar. Starting from the center of the printhead, roll the cloth outwards across the surface of the head, which ensures that a clean portion is always touching the nozzle plate. The last thing that you want to do is push debris from the nozzle plate into the nozzles! Never use a contaminated cloth on the printhead surface, so wipe the printheads one at a time to ensure that debris from one head isn’t transferred to the others. Some printers use automated wipers to make this process easier; however, be sure to still wet and wipe off the wiper itself before using it on the head!

Bad wiper (front) vs good wiper (back)

Stubborn jetouts might call for cleaning the inside of the printhead as well. There are several techniques to do this, depending on the severity of the issue:

- Passive Cleaning — Fill the printhead and subtank with cleaning solution and leave them to soak for a few hours

- Gentle Cleaning — A negative pressure is applied to the underside of the printhead, which pulls fluid through the nozzles for a few seconds. This is often done with a capping station and a pump.

- Medium Cleaning — Pressure is applied to the ink inlet of the printhead, forcing fluid through the nozzles. Sometimes the nozzle piezos are activated to help push ink through the head.

- Extreme Cleaning — Along with apply back pressure, jetting at a high frequency can increase the force on the blocked meniscus and break it free

The best maintenance practice of all is developing an understanding of how the printer works, instead of spending an hour cleaning the printer every morning without understanding the root cause of the issue. LVD Inkjet Services works with clients all over the world, providing consultation and training for end users to help teach them how to identify issues, solve them fast, and get the most out of their printers. They also work with printer manufacturers who want to better understand the performance of their products in the field to help improve their designs and train their team. A big thank you to Luc for sharing his expertise!