Print Station Repeatability Testing Results

ImageXpert has been working to measure the repeatability of our printing systems as demand for high precision substrate handling and printing is growing. We are proud to say that our latest results show <1.5µm stage repeatability (3σ), and we’ve demonstrated 1.5µm print repeatability using our inks and waveforms. We have always prioritized the quality and precision of our instrumentation, and we are excited to have fresh data to prove it.

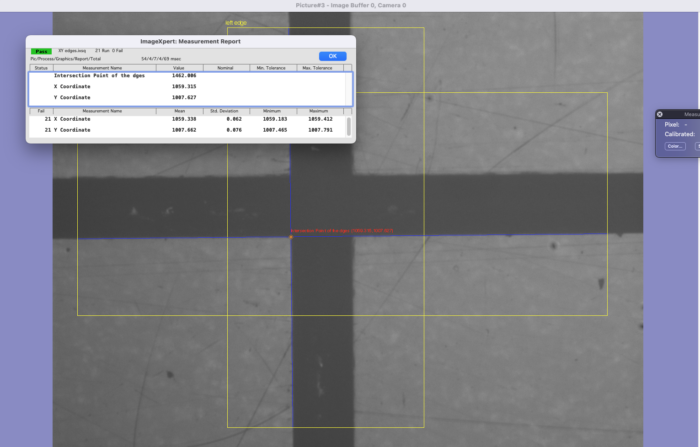

Stage Repeatability Testing Methodology

A calibration target grid was secured to the stages with a high resolution camera positioned above it, focused on an intersection point of the grid. Before moving the stages, the repeatability of the XY coordinate measurements on a stationary target were determined to be less than 100nm. The stages were then moved in the process direction and then returned to the original position, both moves at a speed of 100 mm/s. The image was captured by the ImageXpert machine vision software and the XY coordinates of the intersection location were measured. These steps were repeated to collect a large sample, and the standard deviation of the intersection position was calculated for the process axis. This entire procedure was then repeated with the cross-process direction, and the standard deviation of the intersection position was calculated.

Results show ± 1.0 µm (3σ) stage repeatability for the process axis and ± 1.5 µm (3σ) for the cross-process axis.

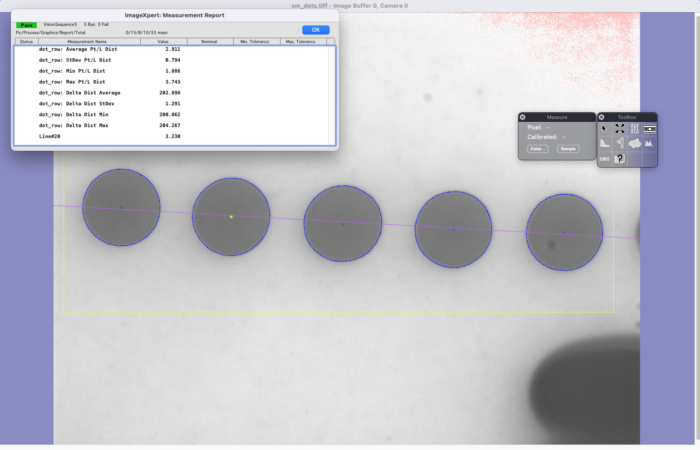

Print Repeatability Testing Methodology

The same high resolution camera setup was used for this testing, along with a Dimatix Starfire SG1024MA printhead and GIS drive electronics. An image of a single dot was printed at 100mm/s and the stage was returned to the starting position. Then the commanded position of the dot (PhysicalPrePrintBufferLength for GIS experts) was increased by 200 µm, and the dot was printed again. These steps were repeated five times to generate a line of six dots, ideally co-linear at equal spacing of 200um. The actual dot positioning was measured using the high resolution camera. These steps were repeated to collect a large sample, and the standard deviation of the dot spacing was reported.

Results show < 1.5 µm print repeatability which includes all variation in drop placement, drive electronics signal handling, and motion stage movements.